In today's fast-paced manufacturing environment, precision and quality are non-negotiable. For many manufacturers, ensuring that every product is accurately labeled is a critical component of the production process. Labeling not only provides vital product information but also ensures regulatory compliance and protects consumer safety. This is where label inspection machines come in—revolutionizing quality control across various industries by automating the label verification process.

This article will delve into how label inspection machines are transforming the manufacturing landscape, improving quality control, and enabling manufacturers to meet the high standards demanded in today’s market.

The Importance of Label Accuracy in Manufacturing

Accurate labeling is a fundamental aspect of product integrity. Manufacturers must ensure that every label accurately reflects the contents of the product, including important information such as expiration dates, ingredients, safety warnings, and product specifications. In industries like pharmaceuticals and food manufacturing, incorrect labeling can result in serious legal consequences, recalls, and health risks.

Regulatory Compliance and Labeling

Regulatory bodies such as the FDA, EU Food Safety Authority, and various consumer protection agencies require manufacturers to meet strict labeling standards. Failure to comply can lead to costly fines, legal repercussions, and damage to a brand’s reputation. Label inspection machines play a crucial role in ensuring that manufacturers comply with these regulations by automating the inspection process.

What is a Label Inspection Machine?

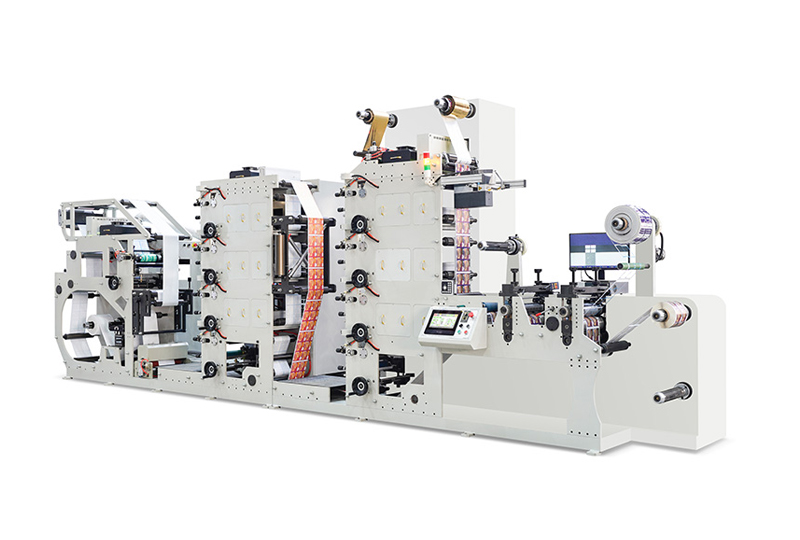

A label inspection machine is an automated system designed to check product labels for accuracy. These machines are typically equipped with high-resolution cameras and optical sensors to examine the labels for defects such as incorrect text, misalignment, missing information, and issues with barcode and QR code readability. By automating this process, manufacturers can quickly detect issues before products leave the production line.

How Label Inspection Machines Function

Label inspection machines use advanced imaging technology to scan the labels applied to products. The process involves the machine capturing detailed images of the labels and comparing them to predefined templates or databases. The machine can detect a variety of defects, from minor misprints to major discrepancies like missing barcodes. If a defect is found, the system alerts the operator for corrective action, allowing faulty products to be removed from the production line.

Key Benefits of Label Inspection Machines

Enhanced Quality Control and Consistency

By automating the inspection process, manufacturers can ensure that every label is scrutinized under the same conditions, leading to improved consistency and quality. This eliminates the variability introduced by human inspectors, who may miss small errors or grow fatigued over time. Automated inspection ensures every label meets the required standards without compromise.

Speed and Efficiency Gains

One of the most significant advantages of label inspection machines is their speed. These machines can inspect labels at a much faster rate than human workers, which accelerates the overall production process. With rapid detection of faulty labels, production lines can continue without interruption, minimizing downtime and maximizing throughput.

Cost Savings in the Long Run

While the initial investment in label inspection machines may seem high, they offer significant cost savings in the long run. By catching errors early in the process, manufacturers can avoid costly recalls, fines, and rework. Additionally, automated inspection reduces the need for manual labor, leading to savings in operational costs.

Reducing Human Error in Labeling

Human error is an inherent risk in any manual process. When it comes to labeling, even the smallest mistake—such as a misplaced decimal point or an incorrect expiration date—can have serious consequences. Label inspection machines eliminate the risk of human error by providing 24/7 precision and consistency. These machines can detect flaws that a human inspector might overlook, ensuring the highest level of accuracy.

Improving Product Traceability with Labeling Machines

Label inspection machines also enhance product traceability, which is crucial for industries like pharmaceuticals and food production. By verifying barcodes and QR codes on labels, these machines ensure that each product can be tracked throughout the supply chain. This level of traceability is essential for recalling defective products and ensuring consumer safety.

Barcode and QR Code Verification

Barcode and QR code verification is a critical function of modern label inspection systems. These codes carry essential product information, such as batch numbers, expiration dates, and inventory data. Label inspection machines can quickly scan and verify that the codes are correctly printed and readable, preventing errors that could affect product tracking and logistics.

Industries Benefiting from Label Inspection Machines

Pharmaceuticals and Healthcare

In the pharmaceutical industry, accurate labeling is essential for ensuring patient safety and compliance with strict regulatory standards. Label inspection machines help pharmaceutical manufacturers avoid errors that could lead to dangerous consequences, such as incorrect drug dosages or misleading instructions.

Food and Beverage

In the food industry, labeling is crucial for providing consumers with accurate nutritional information, ingredient lists, and allergy warnings. Label inspection machines ensure that labels are correctly printed, reducing the risk of violations and improving consumer trust in the brand.

Consumer Electronics and Packaging

In electronics, where product specifications and warranty information are essential, label inspection machines ensure that the labels are clear, accurate, and intact. For packaging companies, ensuring that labels are applied correctly is vital to maintain product integrity and branding consistency.

Choosing the Right Label Inspection Machine for Your Manufacturing Line

When selecting a label inspection machine, manufacturers should consider factors such as speed, accuracy, the complexity of the labels, and industry-specific needs. Different machines offer different capabilities, so it’s essential to choose one that aligns with your production requirements.

Different Types of Label Inspection Machines

There are various types of label inspection machines, including optical systems that visually check labels for misprints, as well as barcode and QR code verification machines. Depending on the complexity of your labeling requirements, you may need a combination of these systems.

Factors to Consider When Selecting a Label Inspection Machine

When choosing a label inspection machine, consider factors such as throughput speed, error detection capabilities, machine integration with existing production lines, and the machine's ease of use. Additionally, ensure that the machine can handle the specific requirements of your industry, whether that involves regulatory compliance or managing different label formats.

The Future of Label Inspection Technology

AI and Machine Learning in Label Inspection

The future of label inspection is closely tied to advancements in artificial intelligence (AI) and machine learning. By continuously refining their algorithms, AI-powered machines will be able to identify even the most subtle defects and adapt to new labeling standards.