In the world of modern manufacturing, precision and efficiency are essential. As production lines get faster and more complex, ensuring that products meet the required standards is more critical than ever. One tool that has become indispensable for manufacturers is the label inspection machine. These machines help streamline the production process by ensuring that every label applied to a product is accurate, readable, and compliant with regulations.

Labeling might seem like a small part of the overall manufacturing process, but it plays a huge role in maintaining product quality and meeting legal standards. In this article, we’ll explore why every manufacturer needs a label inspection machine and how this technology can revolutionize production lines.

What is a Label Inspection Machine?

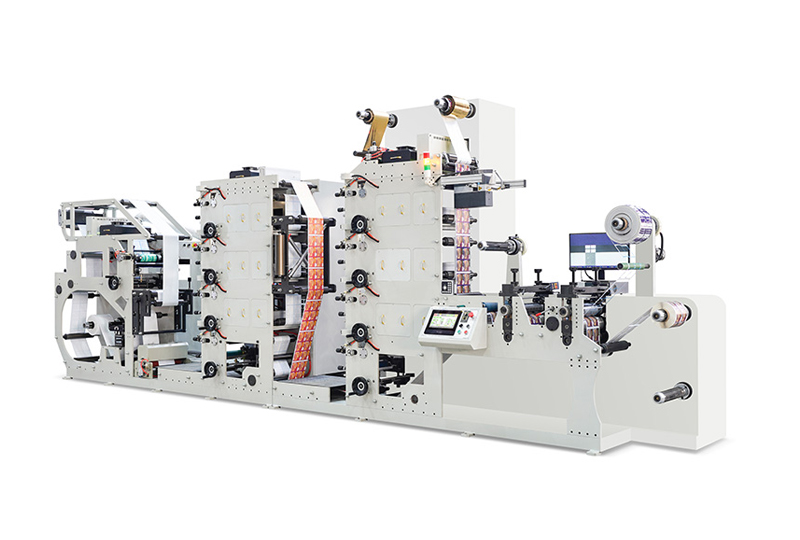

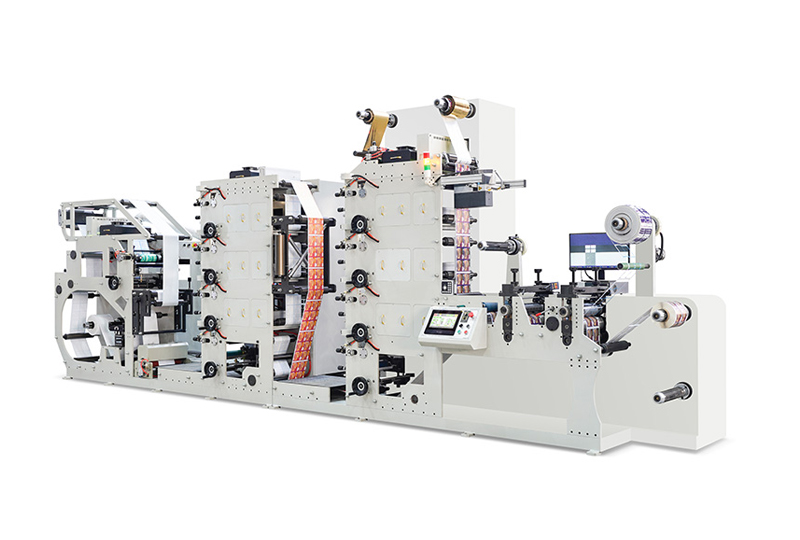

A label inspection machine is an automated device that checks labels applied to products for defects and inconsistencies. The primary function of these machines is to verify that the labels meet specific quality standards. They can inspect for issues like incorrect text, misalignment, missing information, or barcode errors. These machines are commonly used in industries like pharmaceuticals, food and beverage, and consumer electronics, where labeling accuracy is crucial.

How Label Inspection Machines Work

Label inspection machines use advanced technologies such as optical systems, high-resolution cameras, and sensors to scan and analyze labels. These machines are often integrated with software that can detect and flag any issues in real time. The process typically involves the following steps:

Scanning: The machine captures high-resolution images of the label.

Analysis: The software compares the label against predefined criteria (e.g., text accuracy, barcode readability).

Alerting: If a defect is detected, the system alerts the operator, allowing corrective action to be taken immediately.

Some machines can also check labels for regulatory compliance, ensuring that they meet industry-specific guidelines.

The Benefits of Label Inspection Machines

Accuracy and Precision in Labeling

One of the most significant benefits of label inspection machines is their ability to ensure precision. Manual inspection can lead to human error, especially when production lines are fast-paced. With label inspection machines, you get consistent accuracy every time. This eliminates the risk of errors like misspelled text, incorrect information, or misaligned labels.

Increased Speed and Efficiency

In a competitive manufacturing environment, speed is crucial. Label inspection machines can operate at much higher speeds than human workers, allowing for quicker product throughput. By automating the inspection process, manufacturers can keep their production lines moving without delays caused by manual checks.

Consistent Quality Assurance

Maintaining consistent quality across all products is vital for any manufacturer. Label inspection machines ensure that every label is examined under the same criteria, leading to uniform quality. This is especially important for industries where labeling accuracy is regulated, such as pharmaceuticals and food packaging.

Cost Savings in the Long Run

While there’s an initial investment in purchasing and implementing label inspection machines, the long-term savings are substantial. By catching errors early, manufacturers can avoid costly recalls, fines, or customer dissatisfaction. Additionally, automating the inspection process reduces the need for manual labor, which can further decrease operational costs.

How Label Inspection Machines Improve Compliance

Meeting Industry-Specific Requirements

Every industry has specific regulations regarding product labeling. For example, in the pharmaceutical industry, product labels must include precise information about dosage, side effects, and expiry dates. Label inspection machines help ensure that labels meet these stringent requirements, minimizing the risk of non-compliance.

Reducing Risk of Fines and Recalls

Non-compliant or defective labels can lead to serious consequences, including fines, product recalls, and damage to a company’s reputation. Label inspection machines help manufacturers avoid these risks by ensuring that every label is checked for accuracy before the product leaves the production line.

Types of Label Inspection Machines

Optical Label Inspection Machines

Optical label inspection machines use high-resolution cameras to visually inspect labels for defects such as misprints, missing information, or incorrect colors. These systems are ideal for industries that require high accuracy in label design.

Barcode and QR Code Verification Machines

Barcode and QR code verification machines ensure that the product’s barcodes are correctly printed and scannable. These systems are essential for logistics and inventory management, where correct barcode data is crucial.

Overcoming Manual Label Inspection Limitations

The Risk of Human Error

Human error is a natural part of any process, but when it comes to labeling, even a small mistake can lead to significant issues. Manual inspection is prone to errors, especially when workers are tired or under pressure. Label inspection machines, on the other hand, provide consistent, reliable checks without the risk of human mistakes.

Slower Processing Times

Manual inspection is also much slower than automated systems. In high-speed production environments, waiting for a human to check each label can slow down the entire production line. Label inspection machines can quickly detect errors and allow products to continue down the line, improving efficiency.

Implementing Label Inspection Machines in Manufacturing

Assessing Needs and Choosing the Right Machine

Before implementing a label inspection machine, manufacturers should assess their specific needs. Consider factors such as the type of products being labeled, the volume of production, and industry regulations. Choosing the right machine will ensure optimal results and a smooth integration into existing production lines.

Training and Support for Seamless Integration

Integrating new technology into a production environment can be challenging. To ensure a smooth transition, manufacturers should invest in training for their staff. Proper training will help operators understand how to use the machine effectively and how to troubleshoot potential issues.

Future of Label Inspection Machines

Advancements in AI and Machine Learning

As technology continues to evolve, label inspection machines are becoming even more sophisticated. AI and machine learning are being integrated into these systems to improve their ability to detect defects and learn from previous inspections. This advancement will further enhance the accuracy and efficiency of label inspections.

Smart Labeling and the Internet of Things (IoT)

The future of label inspection is closely tied to the rise of smart labeling and IoT. By integrating label inspection machines with IoT-enabled devices, manufacturers can create more connected, efficient production lines. This could allow for real-time monitoring of the entire manufacturing process, including label accuracy.

Conclusion

Label inspection machines are essential for modern manufacturers who want to maintain high standards of quality, speed, and regulatory compliance. These machines provide numerous benefits, including increased accuracy, faster production times, and cost savings in the long term. By investing in label inspection technology, manufacturers can ensure that their products meet both customer expectations and regulatory requirements, all while staying competitive in an increasingly fast-paced market.

FAQs

1. How do label inspection machines work?

Label inspection machines use optical systems and sensors to scan and analyze labels for defects. They check for things like text accuracy, alignment, and barcode readability.

2. What industries use label inspection machines?

Industries such as pharmaceuticals, food and beverage, and electronics rely on label inspection machines to ensure labeling accuracy and compliance with regulations.

3. Can label inspection machines detect barcode errors?

Yes, barcode verification machines are specifically designed to check for errors in barcode printing and scanning, ensuring that they are readable.

4. Are label inspection machines expensive?

The cost of label inspection machines can vary, with prices typically ranging from a few thousand to several hundred thousand dollars, depending on the machine's capabilities and features.

5. Do label inspection machines reduce the need for human labor?

While label inspection machines automate the inspection process, they do not completely eliminate the need for human labor. However, they can reduce the time and labor needed for manual checks.

Türkçe

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

አማርኛ

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

Latine

Dansk

اردو

Shqip

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Māori