Include:

a. Web guide

b. one pcs mould

c. Punching device

d. 4 pcs printing cylinders

e. 4 pcs ceramic anilox rollers

f. 4 pcs doctor blade+automatic tension control for unwinding

Guarantee: one year for mechanical parts,half year for electric parts.the service is for whole life.

Term of payment: 30% deposit and pay the balance before shipment by TT after testing the machine in our factory.

Delivery time: 30 working days after receipt of deposit

Packaging: Seaworthy packing

Transportation: Ocean Shipping

For different cup size, it also need change different mould. So it had better to provide us drawing of opened cup with marked size, so we can make die cutting layout as your reference.

Unwinding device

Equipped with one pcs 3inch air expanding shaft

With magnetic brake and automatic constant tension controller to control unwinding tension

With EPC(web guide system) to correction web horizontal movement

Maximum unwinding diameter is 1300mm

Edge position controller, namely Web guide system

1 set of paper splice table, With Pneumatic Holder

Detection mode: Ultrasonic Sensor

Precision: ±0.1mm

Closed-loop control system

Test method: Edge

Electronic paper web guide traction device, there was a small material web movement, the system can accurately continuously revised.

Hydraulic lifting system for unwinding

(whatever raw material is heavy, it can easy to lift to unwinding location or unload on the ground without labor)

PLC touch screen

Power Supply, Stop Button, Start Button and Emergency Stop.

Temperature control by PLC for each Heating Oven

Anilox Roller Rotation controlled by PLC for each Printing Station

Length Count and Speed Control will display and set on touch screen.

More data will be display and set on PLC control touch screen.

Transmission

(machine mainly using synchronous belt to be drive, it can avoid over lap problem, and not easy to be broken while overwork )

Guide rail for lifting

(Improve precision and easy adjustment)

Printing stations

l each color has equipped with one printing station,one unit printing station has come with

one pcs printing cylinder,one pcs ceramic anilox, one pcs ink rubber roller and one pcs impression roller, one pcs ink container and one pcs scrapper blade

l Vertical overprint adjustment can be adjusted by 360°handwheel.

l Horizontal overprint adjustment can be adjusted by handwheel.

l Helical gear

Flexo plate is stick on printing cylinder. Different printing perimeter need different printing cylinder, normally printing perimeter and web line of ceramic anilox will be told by plate making company.)

Horizontal overprint register

360°register of front and behind side can be

Adjusted,each color has equipped with one unit

Vertical overprint register

Register for left and right side,each color has equipped with one unit register

Drying device

each color has equipped with infrared heating dryer

Infrared heating drying oven is placed on material and after each printing station.

Heating lamp is fixed in each Infrared Heating Drying Oven.

Optional can use UV / LED UV Drying Oven.

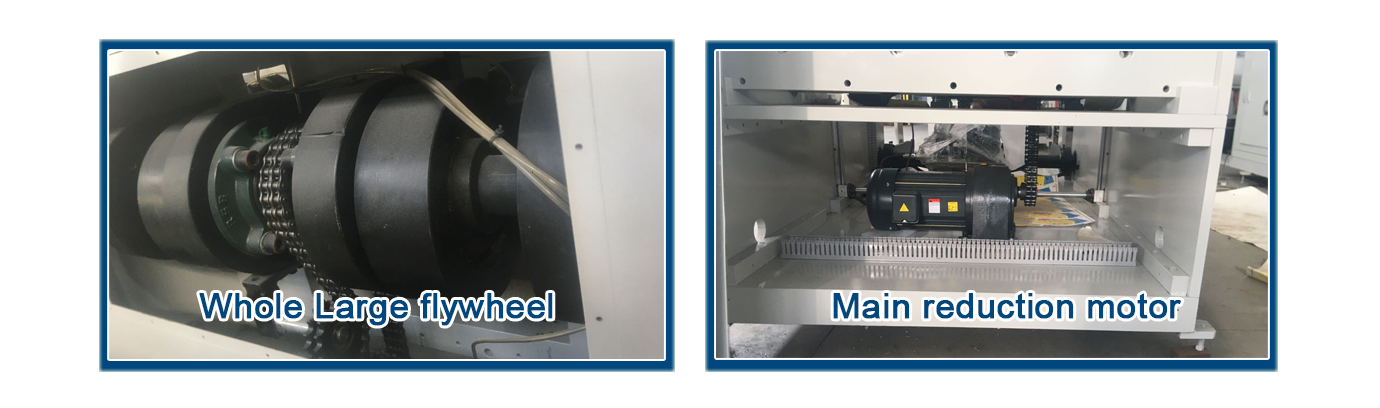

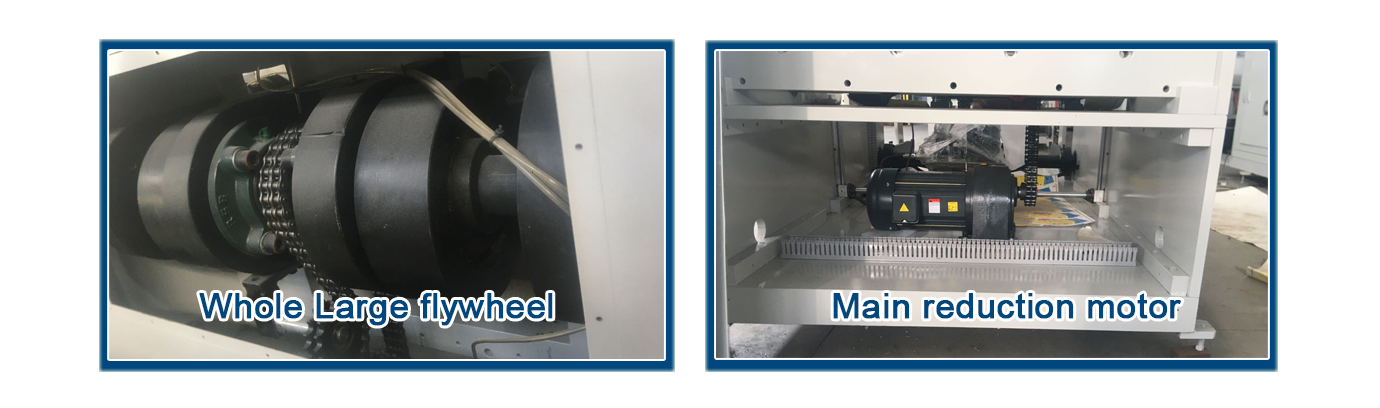

Die cutting Force

The die-cutting force is provided by a 5KW inverter motor driver. It is not only power-saving, but also can realize the stepless speed adjustment, especially when coordinate with the extra large flywheel, which make the die-cutting force strong and steady, and the electricity can be further reduced.

Flywheel driving is done by inverter motor(main reduction motor)

photoelectric eye

The coordination between motor and photoelectric eye which can identify colors assures the

perfectly fit of the die- cutting position and figures.

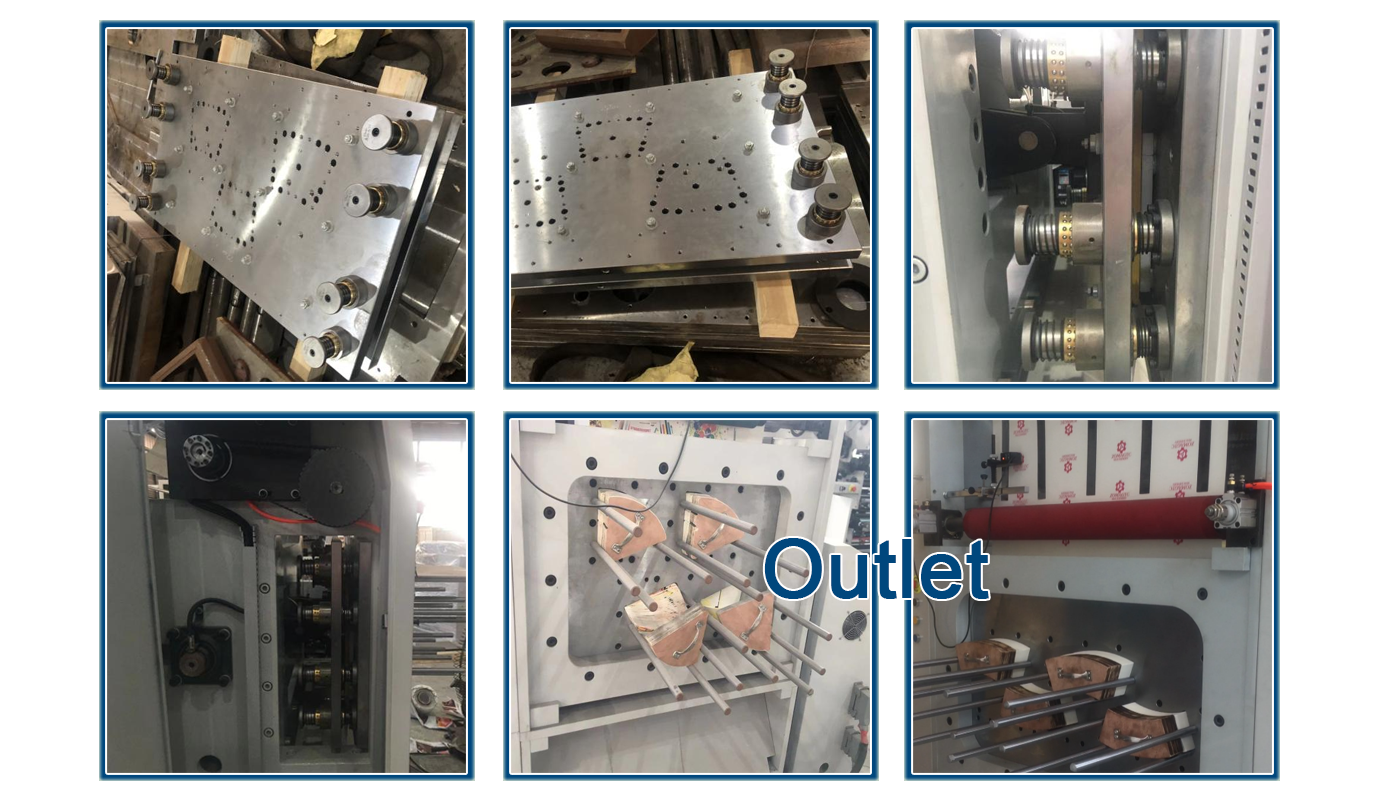

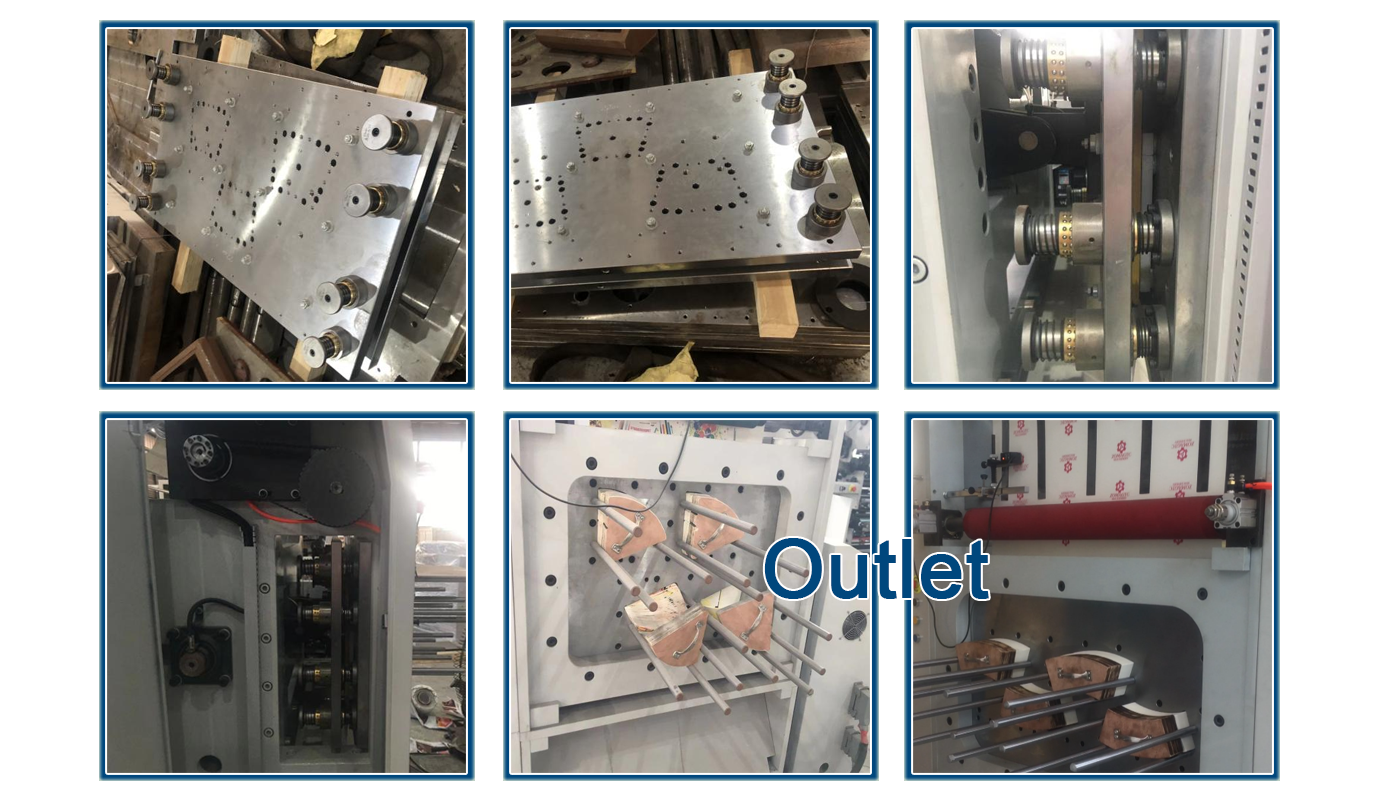

One Set Mould

we adopt good quality material that could be used for long time, and if the mold can’t cut well, you

could polish the blade then continue to use.

Samples pics

Any question, please feel free to let me know.

Best Regards

Miss Mickey

Türkçe

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

አማርኛ

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

Latine

Dansk

اردو

Shqip

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Māori