Choosing the right paper cup printing machine helps your brand do well. You need a machine that fits your speed and print quality needs. It should also work with the materials you use. Custom cups show off your brand and help more people see it. They help your business stand out from others. Automated machines save money on workers and help you make more cups fast. Look at quality, energy use, and printing results. Do not only think about price. This helps you make a good choice for your business in the long run.

Key Takeaways

Pick a paper cup printing machine that fits your needs. Think about how many cups you make each day. Also, plan for your business to grow. This helps you avoid buying a new machine too soon.

Choose a machine that can print on different cup sizes. This lets you serve more customers. It also helps you reach more people in the market.

Learn about the printing technology that works best for you. Flexographic is cheaper for big orders. Digital printing is better for detailed and custom designs.

Pick machines that use less energy. This lowers your bills and helps the environment. Find machines with features that save power.

Check suppliers for their reputation, warranty, and support. A good supplier keeps your machine working well. This helps your business do better.

Production Needs

Volume

You need to know how many cups you want to print each day. If you run a small café, you may only need a few hundred cups. Large factories often print thousands or even tens of thousands daily. When you choose a Paper Cup Printing Machine, match its speed and output to your business size. High-speed cup printers work best for big orders. Small shops can use machines with lower speeds. If you plan to grow, pick a machine that can handle more cups in the future. This helps you avoid buying a new machine too soon.

Cup Size

Cup size matters when you select a printing machine. You may print cups for cold drinks in different sizes, such as 8oz, 12oz, or 16oz. Some machines only print one size, while others adjust for many sizes. Look at the cup’s bottom depth, rim curl, and top diameter. These features affect how cups stack and how lids fit. The table below shows important cup size factors:

Factor | Description |

Cup Bottom Depth & Angle | Changes how cups nest and stack. Helps with packaging. |

Rim Curl and Top Diameter | Decides lid fit and cup strength. |

Market Demand | Some regions prefer certain cup sizes. |

If you serve many markets, choose a machine that prints several cup sizes. This gives you more options and helps you meet customer needs.

Design Complexity

Custom cup printing lets you show off your brand. If you want simple logos, most machines can print them. If you need full-color images or detailed graphics, look for machines with advanced print features. Complex designs may need better registration and color accuracy. Some machines handle only basic prints, while others support high-resolution images. Think about your brand’s style and how you want your cups to look. The right machine helps you create eye-catching designs for cold drink cup production.

By matching your production needs to machine features, you make sure your investment supports your business goals.

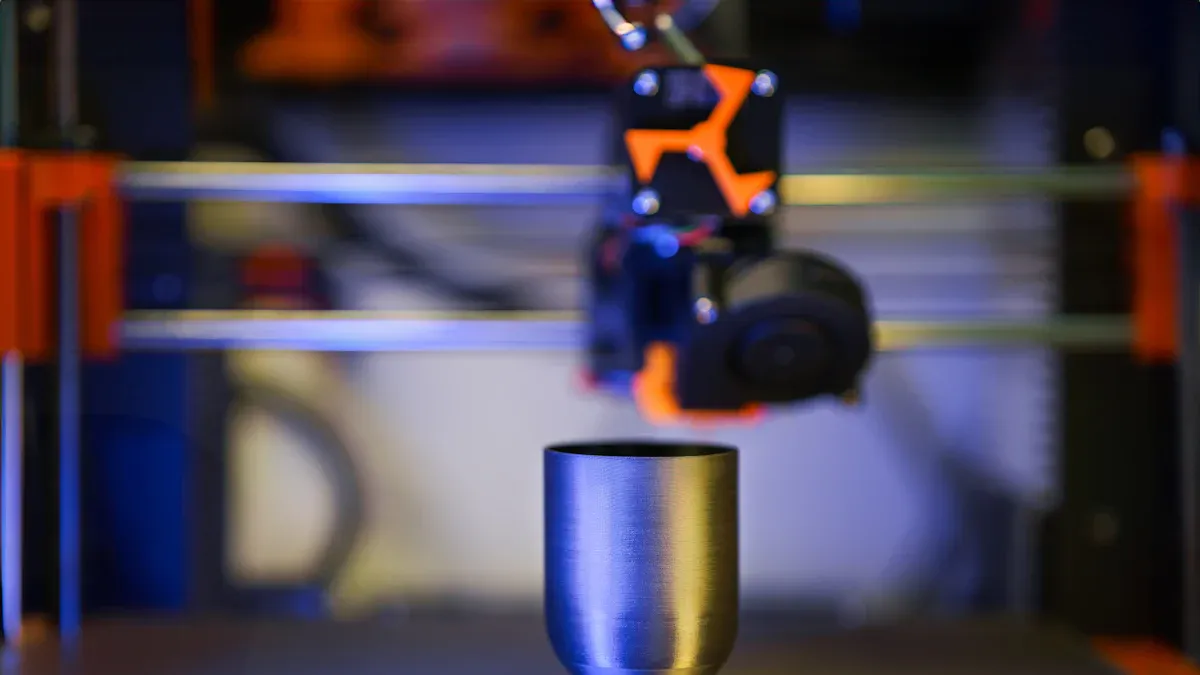

Paper Cup Printing Machine Types

Picking the right Paper Cup Printing Machine depends on your business size. It also depends on how many cups you want to make. There are manual, semi-automatic, and fully automatic machines. Each type has a different speed and level of automation.

Manual

Manual machines are good for small businesses or new shops. You must do each step by hand, like loading and printing. These machines make fewer cups. Production is slow because you handle every cup yourself. Cafes and small restaurants use manual machines when they need only a few hundred cups a day.

Tip: Manual machines are cheaper and easy to learn. You can start fast, but making cups takes more time.

Semi-Automatic

Semi-automatic machines mix manual and automatic steps. You put in the cups, and the machine prints the design. These machines make more cups than manual ones. You still need to help with some steps. Medium businesses, hotels, and event places often use semi-automatic machines.

Note: Semi-automatic machines are great for growing businesses. You do not need full automation yet.

Fully Automatic

Fully automatic machines do every step for you. They feed, print, and stack the cups. These machines make lots of cups very fast. Big factories and brands use them for large orders. You can make thousands of cups each day with little help.

You must install these machines the right way. They need safe power and regular care. Operators should know how to keep them clean and safe. You should check parts and change them if needed. Keeping track of care helps stop breakdowns.

Which Machine Fits Your Business?

You can pick a machine that matches your needs:

Manual machines are best for new shops and small cafes.

Semi-automatic machines fit medium businesses, hotels, and events.

Fully automatic machines are for big factories and brands.

There is a Paper Cup Printing Machine for every business size. Think about how many cups you need, your design plans, and your budget. You can choose a machine that helps your business grow and keeps your customers happy.

Printing Technologies

Picking the right printing technology changes your results and costs. There are three main choices: flexographic, digital, and screen printing. Each one works best for different jobs.

Flexographic

Flexographic printing is good for big orders. It uses flexible plates to put ink on cups. This method is fast and cheap for lots of cups. You can print on many materials and use different designs.

Advantage/Disadvantage | Description |

Cost-Effectiveness | Flexo printing saves money when you print many cups. The cost per cup goes down with bigger batches. |

Speed | Flexo machines work quickly. They help you make lots of cups fast. This is important for big orders. |

Versatility | Flexo printing works on many materials. It can print different designs, so many companies like it. |

High Setup Costs | Setting up flexo printing costs a lot at first. This is hard for small orders. |

Print Quality for Fine Details | Flexo printing is not great for tiny details. It works better for simple designs. |

Limitations for Complex Artworks | Flexo printing has trouble with complex art. Many colors or details make setup longer and cost more. |

Digital

Digital printing gives you sharp prints and lets you change designs easily. You do not need plates, so you can start printing quickly. This method is good for small batches and custom jobs. You can print detailed pictures and use many colors.

Screen

Screen printing uses a mesh to push ink onto cups. You get bright colors and strong prints. This method works well for simple logos and bold art. You can use soy-based inks, which are better for the planet.

Screen printing works on paper, PLA, and some plastic cups.

The prints last a long time, but setup takes longer.

This method is not good if you change designs often.

Each printing technology has good points and limits. Pick the one that matches your order size, design needs, and cup material.

Performance Factors

Speed

How fast your machine works decides how many cups you make. Some automatic machines can make up to 100,000 cups each day. Semi-servo machines make less, which is good for medium needs. If you pick a faster machine, you can make more cups. This helps you earn more money and take bigger orders. Fast cup printers help you work better. More cups mean more money for your business. Pick a speed that fits your usual orders.

Reliability

You want a machine that works well every day. Good machines do not break down often. This keeps your work going and saves you money. If your machine breaks a lot, you lose time and money. Pick machines with strong parts and good help from the maker. Take care of your machine and use easy-to-find spare parts. This helps you stop long waits if something breaks.

Print Quality

How your cups look matters to your customers. Offset printing gives sharp and clear pictures. It is good for big orders and works on paper or plastic. The kind of paper you use is important too. Smooth or eco-friendly paper helps the ink look bright. Digital printing is good for small jobs and lets you change designs. Flexographic printing is fast and works well for simple art.

Offset printing is best for big, high-quality jobs.

Digital printing is good for custom or small orders.

Flexographic printing is quick and good for simple designs.

Material Compatibility

The cup material changes how your cups turn out. PLA cups are good for cold drinks. They do not soak up liquid and keep their shape. Paper cups need a plastic lining so they do not leak. PLA cups also keep drinks cold longer. You can use PP or PET cups for special needs. Always make sure your machine works with the cups you want to use.

Cost Analysis

Initial Investment

You need to plan for the upfront cost when you buy a Paper Cup Printing Machine. The price depends on the type of machine you choose. Manual machines cost less and suit small businesses. Semi-automatic machines cost more but help you print faster. Fully automatic machines have the highest price. You also pay for installation, training, and setup. Some suppliers offer packages that include these services. You should ask about warranty and support before you buy.

Operating Costs

After you buy your machine, you pay for daily running costs. These include printing, packaging, electricity, and labor. Each cup you print has a small cost.

You can lower costs by using energy-saving machines and buying packaging in bulk. Tracking each cost helps you set the right price for your cups.

ROI

You want to know how fast you can earn back your investment. To calculate ROI for your printing machine, follow these steps:

Add up all costs, including the machine price, installation, training, and maintenance for one year.

Estimate your revenue from selling printed cups. Use your production capacity, selling price per cup, and expected demand.

Use this formula: ROI = (Net Profit / Cost of Investment) x 100. Net Profit means total revenue minus total costs.

Note: A higher ROI means your machine pays for itself faster. You can improve ROI by increasing production or lowering costs.

You should review your costs and profits every month. This helps you make smart choices and grow your business.

Printing Results

Color Accuracy

Color accuracy is important for your brand. The right colors help your cups stand out. People notice bright and correct colors first. Studies say color affects what people buy. Most people choose products because of color. Many first impressions come from color use. If your Paper Cup Printing Machine prints the right colors, people remember your brand. Good color makes your cups look nice and professional.

Up to 85% of buying choices are about color.

90% of first thoughts come from color.

Using color well can help people know your brand.

Durability

Durable prints keep your designs looking new. Prints should last even after many uses or long storage. The cup material changes how long the print stays nice. Look at the table below to see how different materials work:

Material Type | Description | Durability Impact |

PET | Clear plastic, used for cold drinks | Stays clear and strong |

PP | Flexible plastic, does not crack easily | Bends and stays strong |

Strong designs and good materials keep cups looking good. Customers like cups that do not fade or break. This helps them think better about your brand.

Registration

Registration means how well colors and images line up. Good registration keeps logos and pictures sharp. Bad registration makes designs look blurry or crooked. You want your cups to look neat every time. Machines with good registration help you waste less and keep quality high.

Tip: Always look at sample cups for registration before buying a machine.

Customization

You can pick many ways to make your cups special. You can use eco-friendly inks, like soy-based or water-based inks. Soy-based ink is safe and breaks down faster than normal ink. Water-based inks use water, which is better for nature. These inks give bright colors and help the planet.

Customization Option | Description |

Sustainable Inks | Eco-friendly inks are safe and break down easily |

Biodegradable Materials | Compostable cups, like PLA-coated paper, break down in nature |

Energy-Efficient Printing | Digital printing uses less power and makes less waste |

You can print detailed logos, bright colors, or special messages. Eco-friendly printing shows you care about the earth and quality.

Maintenance

Taking care of your paper cup printing machine is important. It helps you stop problems and saves money on repairs. Good care also keeps your cold drink cup prints looking nice. You can follow easy steps to keep your machine working well.

Routine Care

Check and clean your machine every day. This helps ink move and parts work right.

You should also do some jobs each week and month. Change gearbox oil and check the wires. Calibrate temperature sensors and look at spare parts. This helps your machine last longer and keeps prints looking good.

Spare Parts

You need to get spare parts for your cup printer easily. Many sellers have lots of parts online. You can find:

Heating coils that make heat for cup making

Nozzles that put materials into molds

Paper pushers that feed paper into the machine

SolutiGreen and other brands make ordering parts simple. Getting spare parts fast means less waiting and better work.

Support

Good technical support helps you fix problems quickly. Many sellers give different kinds of help:

Support Type | Description |

TeleSupport | Phone hotline for quick troubleshooting |

TeleInspection | Online connection for direct system access |

TeleLink | Regular checks to ensure emergency access |

CaseReport | Step-by-step documentation of error reports and fixes |

Third-party support | Service from sub-suppliers for complex issues |

You can also ask for service visits and get expert help. Service bulletins and advice help your machine work its best.

Supplier & Service

Picking the right paper cup printing machine supplier is important. The supplier you choose can help your business do well. You want a supplier who sells good machines and helps you after you buy. Let’s see what you should look for.

Reputation

A good supplier makes you feel safe about your choice. You should check if the supplier gives good service and answers your questions. It is also important that they deliver on time. Henghao is known for making quality machines and keeping customers happy. Use this table to compare different suppliers:

Criteria | Description |

Product Quality | Makes sure your cups are good and safe. |

Delivery Timeliness | Helps you get your cups when you need them. |

Responsiveness to Inquiries | Shows the supplier listens and helps you. |

Quality Assurance Processes | Means the supplier checks their work. |

Company Background | Tells you if the supplier has lots of experience. |

Product Range | Lets you pick machines for many cup sizes. |

Quality Standards | Shows the supplier follows the rules. |

Customer Satisfaction | Good reviews mean happy customers. |

Tip: Always read what other people say and ask for examples before you buy from a supplier.

Warranty

A warranty helps protect your money when you buy a cup printing machine. Most suppliers, like Henghao, give a one-year warranty. This covers the main parts and gives you help if something breaks. Some suppliers also help you fix problems online or update your machine’s software. After one year, you can pay for more coverage if you want extra safety.

The normal warranty is for one year.

It covers main parts and gives you help.

You can buy more coverage for extra safety.

After-Sales

After-sales support helps you fix problems quickly. Henghao and other good suppliers give phone help, online help, and send spare parts fast. You can get help with setting up, learning, and fixing your machine. Good after-sales service means your machine works better and you lose less time.

If you choose a supplier with a good name, clear warranty, and strong after-sales help, your business will do better for a long time.

Pick a machine that fits what your business needs. Think about how much it costs, how good the prints look, and if it will work well for a long time. Make a list to compare things like speed, what cups it can print on, and if you get help from the company. Ask the seller for sample cups and tips. Good help after you buy and following the rules will help your business get bigger.

FAQ

What is the best paper cup printing machine for small businesses?

Manual or semi-automatic cup printers are good for small shops. These machines do not cost a lot and work for small orders. Pick a model that can print on many cup sizes. It should also let you change designs easily. Search for "best paper cup printing machine for small business" to see what is out there.

How often do I need to maintain my cup printing machine?

Clean your machine every day. Check the parts once a week. Change any parts that look old or broken. Taking care of your machine helps it last longer. Always use the care guide from your supplier.

Can I print full-color logos on cold drink cups?

Yes, you can print full-color logos on your cups. Digital printers are best for small jobs and custom art. Flexographic machines are better for big orders. Both types give you bright and clear pictures for your brand.

Are there eco-friendly options for cup printing?

You can pick inks that are safe for the earth, like soy-based or water-based inks. Many machines can print on cups that break down in nature. Search for "eco-friendly cup printing solutions" to find green machines and materials.

How do I choose between manual, semi-automatic, and fully automatic machines?

Pick a machine that matches how many cups you need to print. Manual machines are best for new shops. Semi-automatic machines are good for medium businesses. Fully automatic machines are for big brands. Think about how many cups you make each day and how much money you want to spend.

Türkçe

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

አማርኛ

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

Latine

Dansk

اردو

Shqip

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Māori