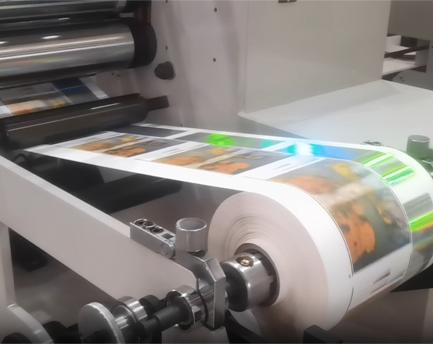

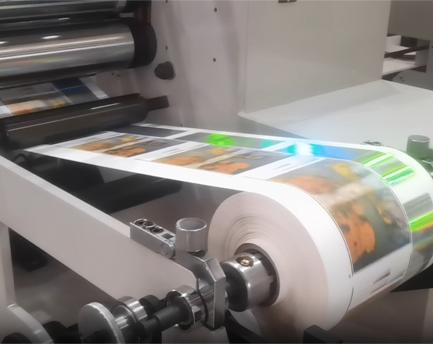

The printing and packaging industry has experienced rapid evolution in recent years, driven by increasing demand for high-quality, cost-effective, and fast-turnaround products. Traditional flexographic printing methods, while effective, have often depended heavily on manual labor for setup, operation, and maintenance. This dependence not only limits production efficiency but also introduces variability in print quality.

The advent of fully automated inline flexo printing machines marks a transformative shift in the flexographic printing landscape. By integrating advanced automation technologies such as servo-driven tension control, automated plate changing, and in-line cleaning systems, these machines have dramatically reduced the need for human intervention. This transformation allows manufacturers to cut labor costs, minimize errors, improve print consistency, and significantly boost production output.

The Impact of Automation in Inline Flexo Printing

From Manual to Intelligent Automated Operations

Historically, flexo printing required skilled operators to manually adjust tension, load and change printing plates, clean rollers, and monitor print quality. These manual interventions are time-consuming, prone to human error, and often result in downtime, especially during color changes or format shifts.

Fully automated inline flexo printing machines revolutionize this process by leveraging smart control systems. Servo motors dynamically adjust substrate tension in real-time based on sensor feedback, ensuring consistent material handling. Automated plate changers reduce changeover times from hours to minutes, allowing flexible production of short runs with minimal downtime. Meanwhile, automated cleaning units prevent ink build-up on rollers, maintaining print sharpness without frequent manual cleaning.

This shift to automation not only enhances print quality consistency but also enables manufacturers to meet increasingly complex customer demands with greater speed and flexibility.

Key Automation Technologies in Inline Flexo Printing Machines

Servo-Driven Tension Control Systems

Tension control is critical in flexo printing because unstable or incorrect tension can lead to misregistration, material wrinkles, or even substrate breakage. Maintaining ideal tension throughout the web path ensures sharp image reproduction and proper ink laydown.

Servo-driven tension control uses advanced sensors to monitor the material tension continuously. The servo motors adjust roller speeds and braking force automatically to compensate for substrate diameter changes or speed variations, maintaining constant tension. This precise control minimizes waste and improves the overall consistency of the print.

With such systems, operators no longer need to manually adjust tension during runs, reducing human error and enabling smoother, more efficient production.

Automated Plate Changing and Cleaning

Printing plate changes are among the most labor-intensive and time-consuming tasks in traditional flexo printing. Automated plate changers utilize robotic arms and precision positioning systems to remove and install plates swiftly, reducing changeover times significantly.

In addition, automatic cleaning systems spray cleaning solutions and use vacuum extraction to clean plate cylinders and anilox rollers during production without stopping the machine. This continuous cleaning process prevents ink drying and buildup, which otherwise causes color contamination and print defects.

Together, these systems enhance production continuity, reduce downtime, and maintain high print quality with minimal operator intervention.

Integrated Real-Time Process Monitoring

Modern fully automated flexo presses integrate cameras, sensors, and software to monitor print quality parameters such as registration accuracy, color density, and substrate tension in real-time. These systems provide instant feedback and automatically adjust printing parameters to correct deviations.

Moreover, predictive maintenance features analyze machine data trends to schedule service proactively before breakdowns occur, maximizing uptime and extending equipment life.

Benefits of Reducing Labor with Automation

Minimizing Errors and Material Waste

Manual operations introduce variability in registration, ink coverage, and tension control, leading to a higher rate of rejects and wasted raw materials. Automation ensures consistent control of key parameters, drastically reducing print errors and scrap rates.

Lowering Labor Costs and Training Requirements

Automation reduces the need for highly skilled operators to perform complex setup and monitoring tasks. This not only cuts labor costs but also shortens the training time for new staff, enabling companies to deploy personnel more efficiently.

Improving Workplace Safety and Conditions

Automation eliminates many hazardous manual tasks such as heavy plate handling, cleaning with solvents, and tension adjustments under tensioned webs. This reduces workplace injuries and creates safer, cleaner production environments.

Enhancing Production Stability and Print Quality

Stable Web Handling for Accurate Registration

Maintaining stable substrate tension with servo control prevents web wandering, stretching, or slackening. This stability is crucial for multi-color printing where precise alignment (registration) between colors is necessary to produce sharp, vibrant images.

Consistent Ink Transfer and Color Reproducibility

Automated systems precisely control anilox roller speed and pressure, ensuring uniform ink film thickness. This consistency is vital for maintaining color accuracy and vibrancy across long production runs and between batches.

Automated Maintenance Extends Equipment Life

Regular cleaning and maintenance performed by automated systems prevent ink buildup, reducing wear on cylinders and rollers. Predictive alerts allow timely replacement of worn parts before quality or operational issues arise, improving overall machine longevity and reliability.

Boosting Production Output and Speed

Rapid Plate Changes for Maximum Flexibility

Automated plate changers reduce changeover time drastically, allowing printers to switch jobs faster and respond quickly to customer demands for short runs and multiple SKUs. This flexibility is essential in today’s dynamic packaging market.

Continuous Operation Reduces Downtime

Inline cleaning and tension adjustment enable machines to run for longer periods without stopping for maintenance or manual adjustments, increasing total effective production time.

Multi-Task Automation Optimizes Efficiency

From unwinding to printing, drying, and rewinding, the entire production process is automated and synchronized to maximize throughput. Operators can supervise multiple presses simultaneously, optimizing workforce productivity.

Real-World Impact in the Packaging Industry

Companies implementing fully automated inline flexo presses report significant improvements: labor cost reductions of 30-40%, productivity gains of over 25%, and material waste reductions exceeding 15%. These benefits translate to lower production costs, faster turnaround times, and better product quality, enhancing competitive advantage in label, flexible packaging, and specialty printing markets.

Furthermore, these machines accommodate a wide range of substrates—from paper and films to aluminum foils—making them versatile for diverse applications like food packaging, pharmaceuticals, and consumer goods.

Conclusion

Fully automated inline flexo printing machines mark a significant advancement in the flexographic printing industry. By incorporating intelligent servo-driven tension control, automated plate handling and cleaning systems, along with integrated real-time quality monitoring, these presses consistently deliver exceptional print quality while significantly reducing reliance on manual labor. This combination not only improves efficiency but also minimizes errors and downtime, allowing manufacturers to meet demanding production schedules with greater ease.

For businesses striving to boost productivity, cut operational costs, and increase flexibility in today’s competitive packaging market, investing in fully automated inline flexo printing technology is essential. Such innovation empowers companies to stay ahead by producing high-quality printed materials faster and more reliably.

To explore how these cutting-edge inline flexo printing solutions can elevate your manufacturing processes, we highly recommend reaching out to Wenzhou Henghao Machinery Co., Ltd. Their experienced team offers expert guidance tailored to your specific needs, ensuring you find the best equipment to optimize your production line. Visit their website or contact them directly to learn more about their advanced machinery and how they can support your business growth.

Türkçe

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

አማርኛ

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

Latine

Dansk

اردو

Shqip

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Māori