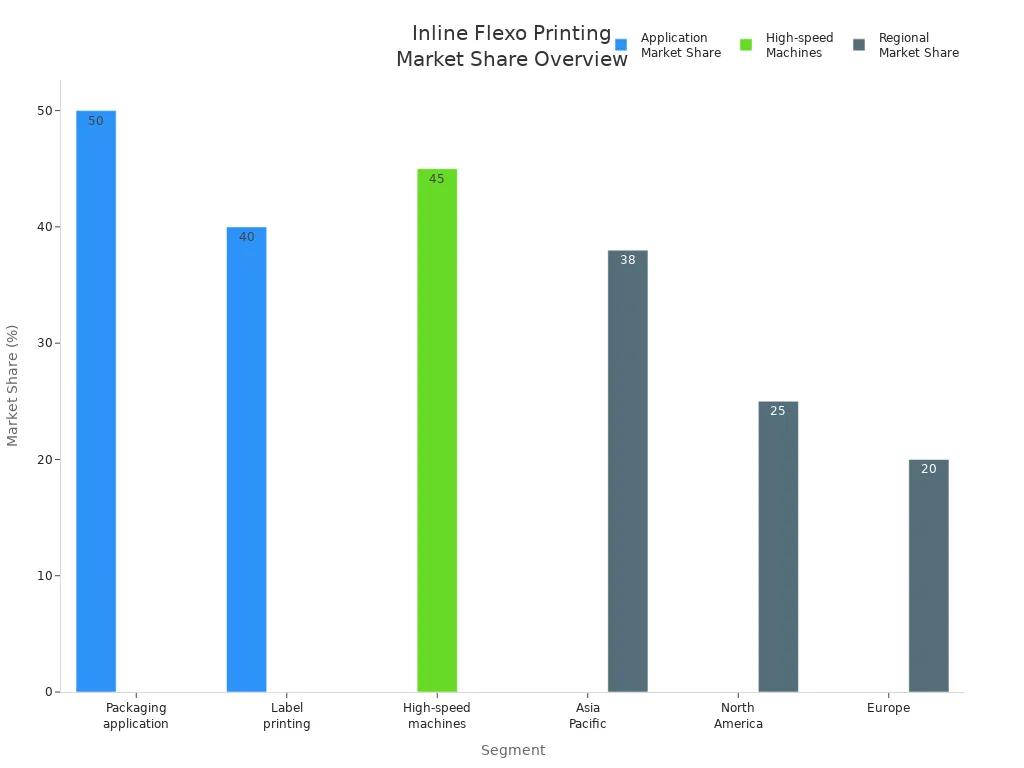

Inline flexo printing machines reshape packaging and labeling by combining printing, die-cutting, and laminating in one high-speed production line. Companies gain efficiency, with production speed improvements of up to 30% and reduced downtime. The global rise in e-commerce drives demand for cost-effective solutions, and inline flexo printing delivers consistent print quality and versatility. These machines support various substrates, making them suitable for many applications across industries. The Asia Pacific region leads market growth, and sustainability trends favor inline flexo printing using water-based inks.

Key Takeaways

Inline flexo printing machines combine printing, die-cutting, and laminating in one fast, automated line, boosting production speed by up to 30%.

These machines deliver high-quality prints with precise color control and work on many materials like plastic films, paper, and aluminum foil.

Automation and integrated finishing reduce errors, waste, and downtime, helping companies save money and meet large packaging demands efficiently.

Flexo printing suits many industries including food, personal care, pharmaceuticals, and industrial labels, offering versatile and reliable packaging solutions.

Despite high initial costs, smart automation and maintenance practices help businesses overcome challenges and enjoy longer machine life and fewer breakdowns.

Inline Flexo Printing Machine Overview

Core Principles

An inline flexo printing machine uses a modern flexographic printing process that combines several steps into one continuous run. This machine integrates printing, varnishing, and die-cutting, which increases productivity and reduces errors. The substrate moves through multiple print stations in a single pass, making the process high-speed and efficient.

Key features of inline flexo printing machines include:

Multiple printing stations, each with its own plate and ink system, allow for precise color matching and registration.

Drying units cure the ink quickly, supporting high-speed operation.

Rewind and unwind stations keep the substrate moving smoothly, which helps prevent jams and errors.

Advanced control systems manage registration and tension, ensuring consistent quality.

The core process starts when the substrate roll feeds into the unwind section. Tension control prevents defects like wrinkling. Ink moves through a doctor blade system to the anilox roller, which applies a thin layer of ink to the printing plate. The plate and impression cylinder transfer the image onto the substrate. After each color, drying units cure the ink. The printed material then rewinds for further use. This step-by-step approach shows how inline flexo printing works and why it delivers reliable results.

Integrated Production Lines

Inline flexo printing machines stand out because they combine several production steps into one automated line. This integration means the substrate does not need to move between separate machines. The production process becomes faster and more precise.

Inline flexo printing connects directly with converting lines, enabling continuous, one-pass operation.

Automation reduces manual handling, which lowers contamination risk and improves hygiene.

Servo-based synchronization keeps registration accurate, so print quality stays high.

Integrating die-cutting and finishing into the flexo printing machines eliminates material transfers, boosting speed and throughput.

The system reduces operational costs by cutting labor and setup times.

Material waste drops because the substrate remains tension-controlled and aligned, minimizing errors.

These key features of inline flexo printing machines make them ideal for high-speed, high-volume production. The process ensures consistent quality and cost savings, which explains how inline flexo printing works better than traditional setups.

Key Benefits for Packaging

Speed and Efficiency

Flexographic printing has transformed packaging production by delivering high-speed results. Inline flexo printing machines use flexible relief plates and fast-drying inks to achieve high-speed printing. These machines often operate at speeds exceeding 300 meters per minute, which allows companies to meet large production quotas with ease.

High-speed printing supports large-volume packaging runs.

Fast ink circulation and effective drying systems keep production moving without delays.

Automation features, such as automatic plate mounting and job changeovers, reduce setup times and minimize human error.

User-friendly controls and maintenance features help operators keep downtime low.

Integrated finishing processes, like die-cutting and laminating, streamline the workflow and reduce manual handling.

Tip: Companies can boost efficiency by using inline flexo printing for both printing and finishing in one continuous process.

These advantages make flexo printing ideal for businesses that need to produce packaging quickly and efficiently. The combination of high-speed production and automation leads to lower operational costs and faster turnaround times.

Print Quality

Flexo printing stands out for its ability to deliver high-quality printed materials. Inline flexo printing machines use advanced technologies, such as anilox rollers and doctor blades, to ensure consistent ink transfer and precise color registration. This results in crisp, clear images and text on every package.

Flexographic printing produces photo-quality four-color process images and Pantone colors on a commercial scale.

Enhanced color precision and image refinement set flexo printing apart from other methods.

Inline finishing capabilities, such as varnishing and die-cutting, help maintain print quality while reducing waste.

Automated registration control and tension systems keep prints aligned and free from defects.

UV drying systems provide instant ink curing, supporting both high-speed and high-quality output.

Flexo printing also accommodates a wide range of inks, including water-based, solvent, and UV-curable types. This flexibility ensures that packaging meets both visual and durability standards. The superior quality of flexo printing means products look appealing and remain protected throughout their shelf life.

Versatility

One of the main advantages of inline flexo printing is its versatility. Flexo printing machines can handle a broad range of packaging materials, from plastic films and paper to aluminum foils and specialty substrates. This adaptability allows companies to serve many industries, including food, beverage, personal care, and industrial packaging.

Flexographic printing supports printing on plastic films (PET, PVC, BOPP, PE), laminated films, paper products, aluminum foils, and even holographic materials.

Enhanced tension control and adaptive drying modules ensure stable print quality across different substrates.

Customization options, such as die-cutting modules and special inks, meet unique packaging needs.

Applications include flexible packaging, self-adhesive labels, folding cartons, and specialty packaging.

Flexo printing technology continues to evolve, now handling compostable films, high-gloss foils, and textured boards. Companies can expand into new markets with confidence, knowing that flexo printing machines offer the adaptability and reliability needed for diverse packaging requirements.

Note: The advantages of inline flexo printing include high-speed operation, superior print quality, and the ability to print on a wide variety of substrates, making it a top choice for modern packaging production.

Applications of Flexographic Printing Machines

Flexographic printing machines play a vital role in many industries. Their versatility and efficiency make them a top choice for both consumer and industrial sectors. The common applications of inline flexo printing include flexible packaging, self-adhesive labels, folding cartons, and security labels. These machines support high-speed production and deliver consistent quality across a wide range of materials. The following sections explore how different industries benefit from the applications of flexographic printing machines.

Food and Beverage

The food and beverage industry relies heavily on flexographic printing for packaging and labeling. Companies use these machines to produce flexible packaging, folding cartons, and labels for products found on grocery shelves.

Bobst’s Whelan notes that there has been rapid growth in demand for labels and flexible packaging particularly in the food and drinks sector, emphasizing the importance of flexibility, agility, and ease of use in flexo presses.

Manufacturers choose flexographic printing because it offers speed, print quality, and adaptability. Inline flexo presses, such as the MIRAFLEX II CI series and Gallus Labelmaster, target flexible packaging printing for food and beverage packaging. These presses handle large, bulky materials like corrugated board and cardboard, making them ideal for retail-ready packaging.

Flexographic printing supports high-volume production of food packaging and beverage packaging.

Machines use low migration inks and LED curing to meet strict food safety standards.

The technology enables rapid curing, reduces energy use, and eliminates harmful emissions.

Inline flexo printing machines allow easy integration of die-cutting and laminating, which suits complex packaging needs.

The common applications of inline flexo printing in this sector include snack bags, juice pouches, bottle labels, and folding cartons. These solutions help companies comply with food safety regulations while maintaining attractive, durable packaging.

Personal Care and Cosmetics

Personal care and cosmetics brands demand packaging that stands out on store shelves. Flexographic printing machines deliver vibrant colors and sharp images, which are essential for these products.

Inline flexo presses, such as the INFLEX and SFX-SLW systems, integrate directly with converting equipment. This setup allows efficient production from raw materials to finished printed products. Automatic speed synchronization, rapid register adjustment, and auto ink circulation ensure high print quality and operational efficiency.

Companies use flexographic printing for printed films, bags, and sheets for cosmetics and personal care packaging.

Integrated lamination and coating processes enhance both appearance and functionality.

The technology supports multi-color printing at high speeds and various material widths.

These features make flexographic printing ideal for flexible packaging and label printing applications in the personal care and cosmetics industry. Brands benefit from reduced waste, faster production, and the ability to create unique, eye-catching packaging.

Pharmaceuticals

Pharmaceutical packaging requires precision, safety, and compliance with strict regulations. Flexographic printing machines meet these needs by offering high-speed production and the ability to print both fixed and variable information.

Inline flexo presses print on blank materials at the time of packaging, reducing the need for preprinted inventory.

Integration with thermal inkjet printers allows for variable data and serialization, supporting compliance with laws like the Drug Supply Chain Security Act.

Machines handle a variety of material thicknesses, making them suitable for blister packs, cartons, and flexible packaging.

Inline flexo printing systems support late-stage customization and improve operational efficiency. Pharmaceutical manufacturers can print complete packages or add variable information inline, streamlining the packaging process and ensuring regulatory compliance.

Industrial and Specialty Labels

Industrial and specialty label printing applications require durability, precision, and the ability to handle large volumes. Flexographic printing machines excel in these areas.

High-precision registration and independently motorized cylinders ensure perfect prints.

Robust components reduce vibration and maintain consistent pressure.

Quick changeovers and cassette-style anilox rolls minimize downtime.

Machines print on one or both sides of various substrates, supporting specialty coatings and inks.

Flexographic printing supports high-speed, large-volume label production. Multiple color stations allow for complex designs and precise color matching. Integration with digital printing attachments enables variable information printing, such as unique barcodes, without slowing production.

The common applications of inline flexo printing in this sector include security labels, industrial tags, and specialty labels for electronics or chemicals. These solutions help companies meet the demands of both consumer and industrial markets.

The Apollo series flexographic presses are compact, user-friendly machines capable of printing high-quality labels and packaging in up to 10 colors. Their small footprint and easy operation suit both label printers and larger industrial operations.

Flexographic printing machines serve a wide range of industries, from food and beverage to pharmaceuticals and industrial labeling. Their adaptability, speed, and print quality make them essential tools in the packaging and printing industries.

Inline Flexo Printing Machines vs. Other Technologies

Digital Printing

Digital printing has changed the way companies produce packaging and labels. It uses computer-controlled inkjet or laser systems to print directly onto materials. This method does not require plates, so setup is quick and easy. Digital printing works best for short runs and jobs that need variable data, such as barcodes or personalized labels.

The table below shows key differences between flexo printing and digital printing:

Aspect | Flexo Printing | Digital Printing |

Print Quality | Consistent color, sharp results for large runs | High resolution, best for fine details and variable data |

Speed | High-speed for large volumes, longer setup | Fast setup, ideal for short runs |

Cost | Cost-effective at scale, higher setup cost | Cheaper for short runs, cost rises with volume |

Flexibility | Less flexible for short runs, hybrid options exist | Highly flexible, great for customization |

Waste & Sustainability | More waste from plates and ink changes | Minimal waste, efficient ink use |

Digital printing offers razor-sharp images and quick turnaround. Flexo printing provides better value for large orders and supports more specialty inks.

Offset and Gravure

Offset and gravure printing are traditional methods used for packaging. Offset printing uses plates to transfer ink onto paper-based materials. It produces crisp images and smooth gradients, making it popular for folding cartons and paper packaging. Gravure printing uses engraved cylinders and excels in ultra-high-volume jobs, such as luxury packaging and flexible films.

The table below compares flexo printing with offset and gravure:

Feature | Flexo Printing | Offset Printing | Gravure Printing |

Substrate Compatibility | Paper, plastic films, foils, cardboard | Mainly paper-based, coated stock, cartons | Films, foils, paper, cardboard |

Production Volume | Medium to high, cost-effective for large runs | Medium to large, slower speed | Ultra-high volume, unmatched consistency |

Print Quality | Solid color, good for large runs | High quality, smooth gradients | Exceptional detail, precise color |

Flexo printing stands out for its speed and ability to print on many substrates. Offset is best for paper, while gravure is chosen for very large jobs and high-end packaging.

When to Choose Flexo

Companies should consider several factors when choosing a printing method for packaging:

Flexo printing is versatile and fast. It works on many substrates, including plastic films and paperboard. This makes it suitable for food packaging, labels, and flexible pouches.

Digital printing is ideal for short runs, prototypes, and jobs that need customization or variable data.

Offset printing delivers high-quality results for paper-based packaging and is cost-effective for large batches.

Gravure printing excels in ultra-high-volume production and luxury packaging with precise color and detail.

Other factors include initial investment, setup costs, sustainability, and operator skill level. Flexo printing machines offer a balance of speed, quality, and adaptability, making them a strong choice for businesses that need efficient, high-volume packaging solutions.

Implementation Challenges

Barriers to Adoption

Many companies in the packaging and labeling industry face challenges when adopting inline flexo printing machines. High capital investment often discourages small and medium-sized businesses from upgrading their equipment. The need for specialized skills to operate and maintain these machines adds another layer of difficulty. Operators must understand how to manage complex systems, including tension control and registration across multiple axes.

Competition from other printing technologies, such as rotary offset and digital presses, also creates barriers. These alternatives can offer lower costs or greater flexibility for certain jobs. Environmental concerns, like the production and disposal of photopolymer plates and the use of chemical-based inks, influence decision-making. Fluctuating raw material prices can affect profit margins and make budgeting unpredictable.

The industry also faces technical hurdles. Long web paths on label presses increase material waste during setup. Down gauging of materials can cause tension control problems. Sophisticated setup features and advanced controls add to the cost and complexity of the process.

Solutions and Best Practices

Companies can overcome these challenges by focusing on automation and smart technology. Automation simplifies the process, reducing the need for highly skilled operators. Features like auto register, auto impression, and job recipe recall help speed up job changeovers and minimize errors. User-friendly interfaces, such as tablet controls, make training easier and faster.

Collaboration between equipment manufacturers and converters leads to tailored solutions that fit specific production needs. Selecting the right plate solutions ensures consistent image reproduction and predictable color, which supports a fast and reliable process. Automation software can optimize plate layouts, reduce waste, and improve print quality.

Digital tools, such as cloud-based management systems and real-time data analytics, help companies monitor production and make better decisions. IoT platforms track costs and support sustainability goals. Modern presses often include energy-efficient drying systems and waste reduction strategies. Hybrid and modular designs allow companies to adapt quickly to changing market demands.

By balancing all steps in the process and standardizing parts, companies can maximize uptime and reduce changeover times. These best practices help businesses stay competitive and meet the demands of a fast-changing industry.

Inline flexo printing machines drive significant transformation in packaging and labeling by improving operational efficiency, print quality, and machine longevity. Companies report up to 50% longer printer lifetimes and 30% to 50% fewer breakdowns, as shown in the chart below.

Industry experts recommend evaluating production needs, material compatibility, and automation features before investing. Businesses seeking reliable, high-speed solutions for packaging should consider inline flexo printing to gain financial and competitive advantages.

FAQ

What types of materials can inline flexo printing machines handle?

Inline flexo printing machines work with many materials. These include plastic films, paper, aluminum foil, and specialty substrates. This versatility helps companies produce packaging for different industries.

How do inline flexo printing machines improve production speed?

These machines combine printing, die-cutting, and finishing in one line. This setup reduces manual handling and shortens setup times. Companies see faster production and less downtime.

Are inline flexo printing machines suitable for small businesses?

Many models offer modular designs. Small businesses can start with basic features and add more as they grow. This flexibility supports both small and large production needs.

What maintenance do inline flexo printing machines require?

Operators should clean rollers, check tension controls, and inspect ink systems regularly. Routine maintenance keeps machines running smoothly and extends their lifespan.

Can inline flexo printing machines support eco-friendly packaging?

Many inline flexo machines use water-based inks and energy-efficient drying systems. These features help companies meet sustainability goals and reduce environmental impact.

Türkçe

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

አማርኛ

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

Latine

Dansk

اردو

Shqip

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Māori