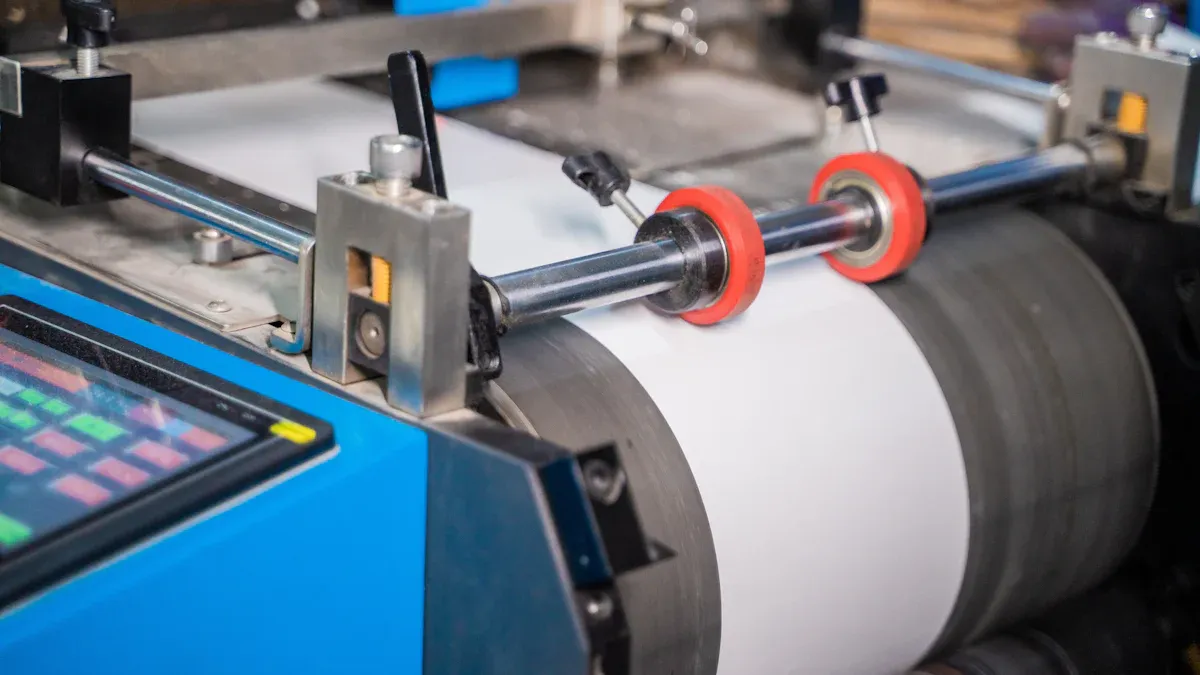

Flexo printing machine technology drives rapid change in the packaging sector. You see key trends like automation, sustainability, and adaptability shaping the future of packaging. Growth accelerates as flexo printing technology enables higher efficiency and supports eco-friendly practices. Leading brands such as Henghao push innovation, helping you gain a competitive edge. Flexo printing offers faster changeovers, improved quality, and flexible production for packaging producers. The latest market data shows strong growth and adoption worldwide, especially in Asia Pacific, with sustainable solutions becoming the standard.

Key Takeaways

Flexo printing machines use automation and smart technology to speed up production, reduce errors, and save materials.

Hybrid machines combine flexo and digital printing to offer high quality, flexibility, and cost savings for different job sizes.

Advanced imaging and eco-friendly inks improve print quality while supporting sustainable packaging goals.

Modular machine designs and broad substrate compatibility let you adapt quickly to market changes and new materials.

The flexo printing market is growing worldwide, driven by demand for faster, greener, and more customizable packaging solutions.

Flexo Printing Machine Trends

Automation & Workflow

You see automation leading the next generation of flexo technology. Modern flexo printing machines now use intelligent automation systems that transform how you manage production. These advancements in automation allow seamless transfer of job data between software and hardware, making press operation more precise and efficient. Automated plate mounting with RFID and cloud integration ensures quick, accurate registration, which reduces setup time and waste. Automated tuning of press drives with advanced algorithms stabilizes operation and improves registration accuracy.

User-friendly interfaces now guide you through changeovers, reducing errors and time, even if your staff has less experience. Robotics and automatic sleeve changeover devices minimize manual intervention, which cuts downtime. Ink cartridge systems and automatic wash-up processes save ink and further reduce downtime. Advanced quality control systems maintain consistent print quality at high speeds, so you can trust every job meets your standards.

Many companies, like Henghao, lead the way in eco-friendly and automated flexo printing machine solutions. They help you streamline workflows, minimize makeready times, and improve print quality. Industry 4.0 principles now enable you to collect and analyze production data, optimize machine settings, and reduce waste. Machine learning algorithms recommend optimal configurations, so you can maximize efficiency and reduce reliance on operator skill. Cloud-based production control tools support smart factory implementations, boosting productivity and reducing downtime.

Workflow automation also connects your entire operation. For example, integrating Management Information Systems (MIS) with your flexo printing technology automates processes from job intake to delivery. This reduces manual steps, eliminates bottlenecks, and improves job tracking. Automated job import, preflight, and editing tools ensure files are ready before processing. Integration with MIS/ERP systems automates step-and-repeat, imposition, and reduces manual intervention. These features collectively improve speed, quality, and error reduction, optimizing your flexo printing workflow.

Hybrid & Combination Machines

Hybrid and combination machines represent one of the most exciting emerging innovations in flexo printing. These presses combine flexographic and digital technologies, merging flexo's high-speed, cost-effective production with digital's precision and customization. You benefit from superior print quality, with crisp, detailed images and vibrant colors. Hybrid presses offer enhanced flexibility, handling a wider range of applications and substrates than traditional flexo presses.

In-line finishing options such as die cutting, embossing, and laminating allow you to produce fully finished products in a single pass, reducing waste and production time.

Hybrid presses enable faster setup and reduced waste compared to traditional flexo presses.

While traditional flexo excels in large volume, consistent runs, hybrid presses are especially beneficial for short to medium runs and jobs requiring customization.

Automation features allow immediate job transitions, pre-programmed print settings, and in-line finishing, reducing staffing costs and print times.

Hybrid presses consolidate production by converting, decorating, and finishing products in one pass.

The market for hybrid flexo printing machines is growing rapidly. By 2025, the market value is expected to reach $2 billion to $2.5 billion, with a strong adoption rate, especially in Europe, North America, and the fast-growing Asia-Pacific region. You see this growth driven by demand for high-quality, cost-effective, and sustainable packaging, as well as the need for shorter print runs and customization. Henghao stands out as a leader in this space, offering advanced hybrid solutions that help you stay ahead of market trends.

Digital Integration

Digital integration marks another major advancement in flexo printing technology. Flexo-digital hybrid solutions let you switch between printing technologies within one machine, supporting both long and short runs efficiently. Digital printing benefits short-run, customized orders, while flexo excels in high-volume production. This combination gives you broad service capabilities.

Automation and AI now enable real-time monitoring, automated setup, and predictive maintenance, improving speed and print quality.

Customizable modular machines increase your production flexibility and reduce operational costs by minimizing the need for multiple standalone machines.

AI-powered control systems improve automatic register and color correction, enhancing precision.

Closed-loop inspection systems detect defects in real time, increasing quality control.

Flexo adapts to smart packaging trends by integrating variable data printing, smart labels, and printable conductive inks.

Digital front-ends (DFEs) enable flexo presses to perform variable data printing and mass customization, allowing you to create unique prints without slowing production. Hybrid flexo machines integrate digital inkjet modules, combining flexo’s speed and cost-efficiency with digital’s personalization and versatility. Automation includes robotics for tasks like plate mounting and cleaning, reducing setup time and human error. Advanced sensors and IoT connectivity link flexo machines with MES, ERP, and cloud platforms, enabling real-time monitoring and data-driven production control.

You gain several benefits from integrating digital technologies with flexo printing processes:

Use digital printing for fast turnaround and on-demand capabilities during product introduction phases.

Switch to flexo printing for mass production to lower costs as demand grows.

Return to digital printing in decline phases to minimize inventory and obsolescence costs.

Employ digital printing for customized or regional product lines where smaller runs are needed.

Use digital printing for proofing flexo jobs to save time and money.

Combining both technologies maximizes cost savings, production efficiency, and waste reduction.

With these advancements and emerging innovations, you can meet evolving customer demands, improve sustainability, and stay competitive in the fast-changing packaging market.

Flexographic Printing Trends

Imaging & Quality Advances

You see major advancements in flexographic printing technology transforming the quality and consistency of packaging and labeling. Digital imaging technology now lets you achieve vibrant colors and sharp details, even on complex designs and a wide range of materials. This progress means flexographic printing can match the quality of gravure printing, which was once considered the gold standard.

Advancement Area | Description | Impact on Print Quality |

Aniloxes | Finer linescreenings with new cell structures | Improved ink transfer and detail resolution |

Inks | Better pigmentation and slower drying | Enhanced color strength and reduced dot bridging |

Repro Tools | New tools for highlights and shadows | Better tonal range and image depth |

Plate Exposure | LED technology and new exposure solutions | Enhanced plate quality and ink transfer |

Plates | Flat top dots and improved surfaces | Sharper dots and significant quality improvements |

Machines | Digitalization and press stability | Increased print consistency and productivity |

You benefit from these advancements because they resolve issues like dot bridging, halo effects, and poor color strength. New imaging techniques, such as CDI Quartz at 4,000 ppi, let you print fine lines and small text without distortion. Q-Cells microcell structures improve ink transfer, giving you stronger solids and smoother gradients. XPS Crystal Exposure systems provide uniform UV LED exposure, preserving fine details and ensuring consistent results.

Direct-to-plate imaging systems and high-definition flexo plates now achieve line screens of 150+ lpi. You get smoother gradients and sharper text. Flat-top dots resist compression, so you see less dot gain and more consistent ink transfer. Microcell surface technology controls ink transfer, improving solid coverage and highlight reproduction. Inline inspection systems detect defects in real time, so you maintain high quality without manual checks.

Cloud-based workflow management connects your production stages, making it easier to respond quickly and keep output consistent. These flexographic printing trends show how advanced flexo printing continues to raise the bar for quality and efficiency.

Expanded Gamut & Sustainability

You notice that sustainability trends and color accuracy are now closely linked in flexographic printing. Expanded color gamut (ECG) technology lets you print a wider range of colors using a fixed set of inks, usually CMYK plus orange, green, and violet. This approach reduces the need for spot colors, which cuts costs and waste from storing and handling multiple inks.

ECG printing allows you to use the same ink set for most jobs, improving press stability and reducing color drift.

Fewer spot colors mean less ink waste and lower overall ink consumption.

Improved color accuracy and consistency lead to fewer reprints, which saves paper and other resources.

Simplified inventory management results from fewer spot colors, reducing storage needs and waste from unused inks.

Advancements in plate screen resolutions, ink viscosity control, and anilox engraving have made ECG printing more predictable and efficient. Apex International’s GTT 2.0 engraving technology, for example, improves ink transfer consistency, making ECG easier to implement. These improvements support sustainability trends by reducing waste and improving press efficiency.

You also see that sustainable packaging is now a top priority. Flexographic printing technology supports this shift by using water-based and UV-curable inks, which lower VOC emissions and energy use. Water-washable plates eliminate harmful solvents, cutting hazardous waste. Many printers now use biodegradable and recyclable substrates, such as plant-based films and recycled paper, to meet consumer demand and reduce landfill waste.

Flexographic printing aligns with global packaging regulations and consumer expectations by adopting eco-friendly inks, energy-efficient equipment, and closed-loop recycling systems. These practices help you meet regulatory requirements and build a strong reputation for responsible packaging.

Linerless Labels & Eco Solutions

Linerless label technology is one of the most exciting advancements in flexo printing. You can now produce labels without a release liner, which reduces waste and supports sustainable packaging goals. The process involves several steps:

Place large rolls of face material (paper or film) on an unwind system.

Print the substrate using flexographic printing stations.

Apply a UV-curable silicone release coating.

Add a pressure-sensitive adhesive to the underside.

Slit the roll into narrower rolls.

Deliver finished rolls of linerless material to the market.

Recent innovations, such as the new MPS press from Coveris, let you print on both paper and filmic substrates. E-Sleeve print capabilities improve accuracy, reduce waste, and speed up setup times. The press features 100% web inspection for quality control and supports multiple label formats, including Slidewrap, c-wrap, envelope, punnet labels, and contour-fitted Skinpack solutions. Cold foil embellishment adds decorative finishes without compromising performance.

Flexographic printing remains a top choice for linerless labels because it handles high-volume runs and delivers excellent print quality on various substrates. You benefit from vibrant colors and intricate designs, which meet the growing demand for high-quality, sustainable packaging and labeling.

Eco-friendly solutions in flexographic printing go beyond labels. You use reusable rubber or polymer plates, which can be reused many times, reducing waste compared to conventional methods. Water-based inks, biodegradable substrates, and energy-efficient equipment all contribute to waste reduction and lower environmental impact. These practices make advanced flexo printing a strong option for companies focused on sustainability trends and efficient packaging production.

Efficiency & Cost

Fast Changeovers

You can boost your operational efficiency by using flexo printing machines designed for rapid changeovers. Modern presses like the MASTER CI 90SIX use cantilever sleeve systems, which let you switch jobs quickly and minimize downtime. Automation features such as smartDROID and smartCLEAN II help you clean and set up print units fast. Automatic splicing completes in under two minutes, saving substrate and speeding up reel changes. The smartTHREAD web threading system moves material from unwinder to rewinder in less than three minutes, so your machine gets ready faster. Digital proofing and offline quality checks with smartGPS II support high-speed production and fewer interruptions.

Quick job changeovers and fast-to-color performance help you meet the demands of shorter print runs.

Improved on-press performance reduces unscheduled stops, increasing profitability.

Automation features like job recipe recall, auto register, and auto impression reduce manual errors.

Tablet interfaces make operator training easier, so you can change jobs faster.

Machines such as Nilpeter’s FA-Line let you store and recall parameters for repeat jobs, which enhances efficiency.

These features allow you to handle more jobs per shift and respond quickly to market changes.

Downtime Reduction

You experience less downtime with new flexo printing machines compared to older models. Advanced technology enables quicker setup and job changes, which means higher productivity. Older machines often slow you down because they lack automation and have outdated parts. Modern presses use integrated automation for printing, slotting, die-cutting, folding, gluing, and ejecting. This reduces manual intervention and setup time. Precise registration and strong construction ensure reliable operation. Routine maintenance and software updates keep your press running smoothly. You spend less time troubleshooting and more time printing, which leads to smarter production.

Supply Chain Benefits

Advanced flexo printing machines offer measurable supply chain benefits. You see increased uptime, less troubleshooting, and reduced waste. Better print control and wider print latitude minimize material waste. Standardized results allow smoother job scheduling and faster changeovers. Printing with fewer colors lowers material costs and simplifies supply chain complexity. Greater tolerance in print conditions leads to higher productivity and less rework. Consistent and predictable results enable "printing by numbers," which reduces variability and manual adjustments. Faster production speeds and cost-effectiveness for mid- to long-run jobs improve supply chain efficiency. Enhanced sustainability supports your environmental goals.

Quantifiable Supply Chain Benefit | Description |

Increased Uptime | Longer continuous production runs with less downtime. |

Less Troubleshooting | Fewer interventions due to improved consistency. |

Reduced Waste | Minimized material waste during production. |

More Efficient Job Scheduling | Smoother scheduling and faster changeovers. |

Fewer Colors Used | Lower material costs and simpler supply chain. |

Wide Print Latitude | Higher productivity and less rework. |

Standardized and Predictable Results | Less variability and manual adjustments. |

Increased Production Speed | Faster throughput with advanced technology. |

Cost-effectiveness for Mid- to Long-Run Jobs | Better efficiency for longer print runs. |

Enhanced Sustainability | Supports environmental goals in the supply chain. |

You can measure your return on investment by tracking jobs completed per shift, reduced setup waste, and energy savings. Automation can cut setup waste by up to 50%. Real-time performance data helps you optimize your process and improve profitability.

Adaptability in Flexo Printing

Modular Designs

You can increase your production flexibility with modular designs in flexo printing machines. These systems let you build your printing line using plug-and-play components. You choose the units you need, such as extra print stations or finishing modules, and add them as your business grows. This approach helps you scale up without buying a whole new machine.

Modular designs support quick job changes and reduce setup times.

You can adjust your workflow to handle new substrates or add finishing units for special effects.

These features help you respond to changing market demands and optimize your investment.

You future-proof your operation by upgrading only the parts you need.

With modular systems, you stay ready for new packaging trends and advancements in technology.

Substrate Compatibility

Flexo printing machines work with many types of substrates. This broad compatibility lets you serve different industries and expand your market reach. The table below shows some common substrates and their benefits:

Substrate Type | Attributes & Benefits | Market Impact & Application |

Paper | Versatile, recyclable, flexible | Used in packaging, labels, newspapers; supports sustainability trends |

Polyethylene | Durable, plastic-based | Used in various product segments |

Plastic Film | Lightweight, durable, cost-effective | Popular for flexible packaging and labeling |

Paperboard | Used in food, beverage, pharma, cosmetics | Largest market share; high demand across industries |

Aluminum Foils | Packaging, insulation | Niche use; driven by food and beverage industry |

Flexible Packaging | Convenience, portability | Rapid growth; meets consumer demand for flexible solutions |

Corrugated Cardboard | Durable, industrial packaging | Important for shipping and industrial sectors |

Folding Cartons | Used in industrial packaging | Supports industrial sector needs |

You can print on plastic, metallic films, and paper. This versatility supports the rise of flexible packaging and helps you meet the needs of e-commerce, food, and industrial markets. Advancements in substrate compatibility allow you to offer more options to your customers.

Customization

You gain a strong advantage when you use flexo printing machines that support customization. You can match brand colors exactly and keep your packaging consistent across different materials. Advanced color management systems and integrated software help you meet strict color standards. This consistency builds trust with your customers and keeps your brand identity strong.

Hybrid flexo technology lets you print variable data, create regional packaging, and run limited editions. You can respond quickly to market trends and produce multiple SKUs with the same high quality. Customization also allows you to add security features or seasonal designs, making your packaging stand out on the shelf. These advancements help you connect with consumers and build brand loyalty.

Market Outlook

Growth Projections

You see strong growth shaping the future of flexographic printing. Market analysts expect the global flexographic printing machines segment to expand rapidly through 2030. The table below shows future market projections from leading sources:

Source | Market Segment | CAGR (%) | Forecast Period | Market Size Start (USD million) | Market Size End (USD million) |

Grand View Research | Flexographic Printing Machines | 9.7 | 2025 - 2030 | 17,568.4 (2024) | 30,562.9 (2030) |

Maximize Market Research | Flexographic Printing Machines | 6.0 | 2024 - 2030 | 537.97 (2023) | 808.90 (2030) |

PS Market Research | Overall Flexographic Printing | 4.3 | 2024 - 2030 | 9,010.9 (2024) | 11,581.4 (2030) |

These future market projections show consistent growth, with rates ranging from 4.3% to 9.7%. You can expect the growth of flexo printing to continue as automation and sustainability drive competitiveness.

Regional Trends

You notice different growth patterns across regions. North America leads in flexographic printing adoption because of its strong packaging industry and early technology uptake. You benefit from eco-friendly solutions and smart manufacturing, including IoT-enabled presses. Europe focuses on sustainability, using water-based inks and UV curing systems to meet strict regulations. Asia-Pacific experiences the fastest growth of flexo printing, driven by booming packaging industries in China and India. You see rapid market expansion, increased investment in advanced presses, and government support for sustainable practices. Each region shapes the future of flexographic printing by prioritizing innovation and efficiency.

Customer Demands

You face evolving future customer demands that influence the growth of flexo printing. Customers want quicker turnaround times and higher print quality. You need machines with faster speeds, easier controls, and designs that allow quick changeovers. Automation features help you monitor and adjust process variables, increasing efficiency and profits. You see demand for sustainable substrates, recyclable plastics, and paper-based products. Customers expect presses to handle new materials like biodegradable pouches and compostable bags. The rise of e-commerce and flexible packaging drives the need for customization and frequent updates. You must adopt automation, AI, and IoT to improve accuracy, reduce waste, and lower costs. These trends shape the future of packaging and ensure you stay competitive.

Automation and sustainability now define the competitive landscape. You gain an edge by investing in eco-friendly inks, energy-efficient processes, and smart technologies. The growth of flexo printing depends on your ability to meet future customer demands and adapt to changing market conditions.

You see flexo printing machine technology driving a smarter and more sustainable packaging future. Leading brands like Henghao deliver high-speed, customizable solutions that help you meet changing demands. Companies adopting advanced flexo printing have reduced costs and improved quality, as shown below:

Company Type | Impact |

Snack Food Manufacturer | 30% lower costs, 20% better print quality, faster response |

Eco-friendly Packaging Company | Increased market share with water-based inks and recyclables |

Explore resources from industry experts and cloud-based platforms to stay ahead in the future of packaging.

FAQ

What is a flexo printing machine?

A flexo printing machine uses flexible plates to print on many materials. You can print packaging, labels, and cartons. The process works fast and supports high-quality, eco-friendly production.

How does automation improve flexo printing?

Automation helps you reduce setup time and errors. You can change jobs quickly and keep print quality high. Automated systems also lower waste and boost productivity.

Can flexo printing support sustainable packaging?

You can use water-based inks and recyclable substrates with flexo printing. Many machines, like those from Henghao, help you meet eco-friendly goals and reduce environmental impact.

What types of materials can you print with flexo technology?

You can print on paper, plastic film, foil, and cardboard. Flexo machines handle many substrates, so you can serve different industries and packaging needs.

Why should you choose Henghao flexo printing machines?

Henghao offers advanced automation and eco-friendly features. You get reliable performance, high speed, and flexible options for your packaging business.

Tip: Choose machines with modular designs for easy upgrades and future growth.

Türkçe

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

አማርኛ

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

Latine

Dansk

اردو

Shqip

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Māori