Triticum excudendi est a printing modum utitur elastica letterpress laminis. Non est bonum printing qualis, adaptat ad amplis printing materiae, princeps productio efficientiam, convenient operationem et sustentacionem, humilis investment, princeps prodest, et obviam environmental tutela. A serie de commoda facere flexo excudendi printing solutio electionis pro variis packaging products.

De flexo printing

Triticum excudendi est letterpress printing modum. Erat primum dicitur Flexographic excudendi. Eam originated in Civitatibus Foederatis Americae in mane 1920s. Hoc defecit ut develop quia aniles tinctura atramento usus est toxicus.

Post hoc, atramento manufacturers coepit utor colorants quod esset gratum ad omnes, et quod renamed flexo excudendi (Flexographic processus) ad 14th American packaging Symposium in MCMLII.

In 1970s, cum ad profectum materiae industria, praesertim adventum Polymer resinae laminis et Curgo Anilox Rollers, progressionem flexo printing fecit a qualitaque saltu.

I. principium flexo printing

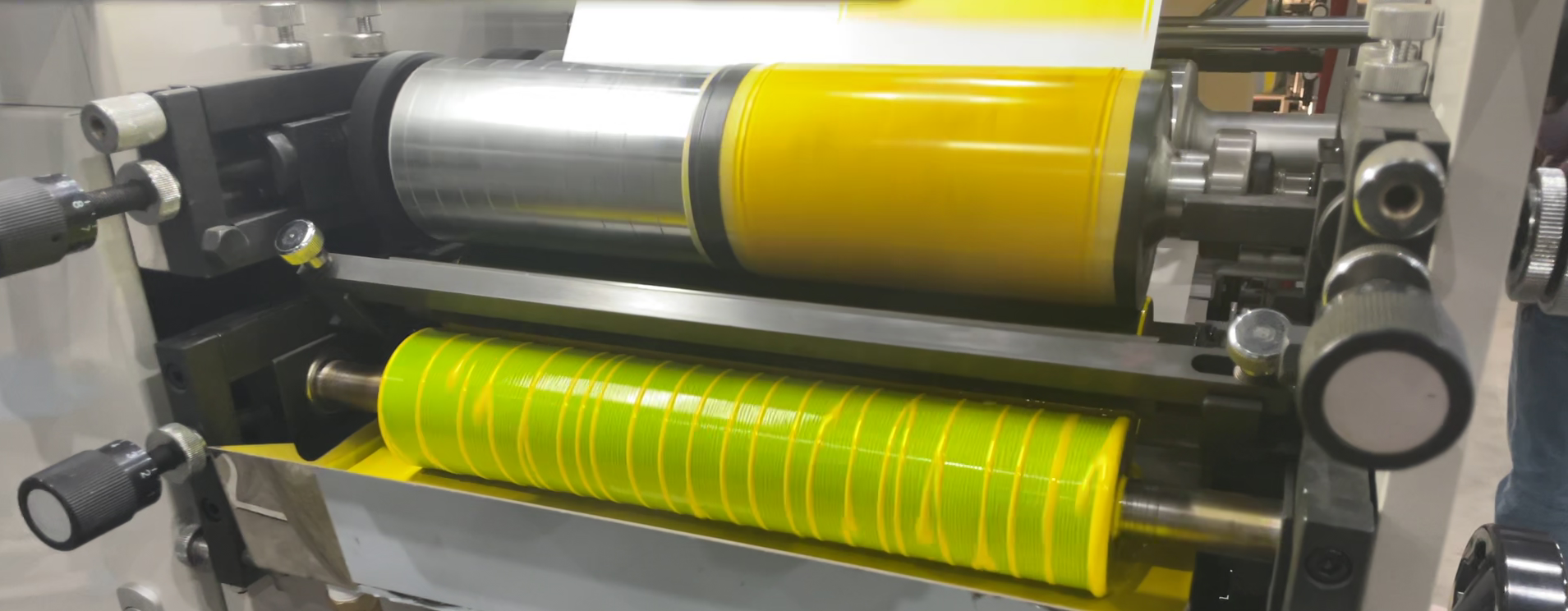

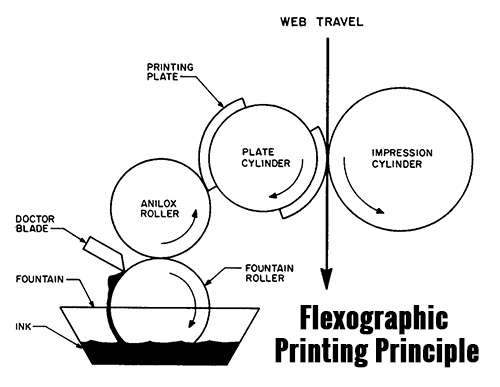

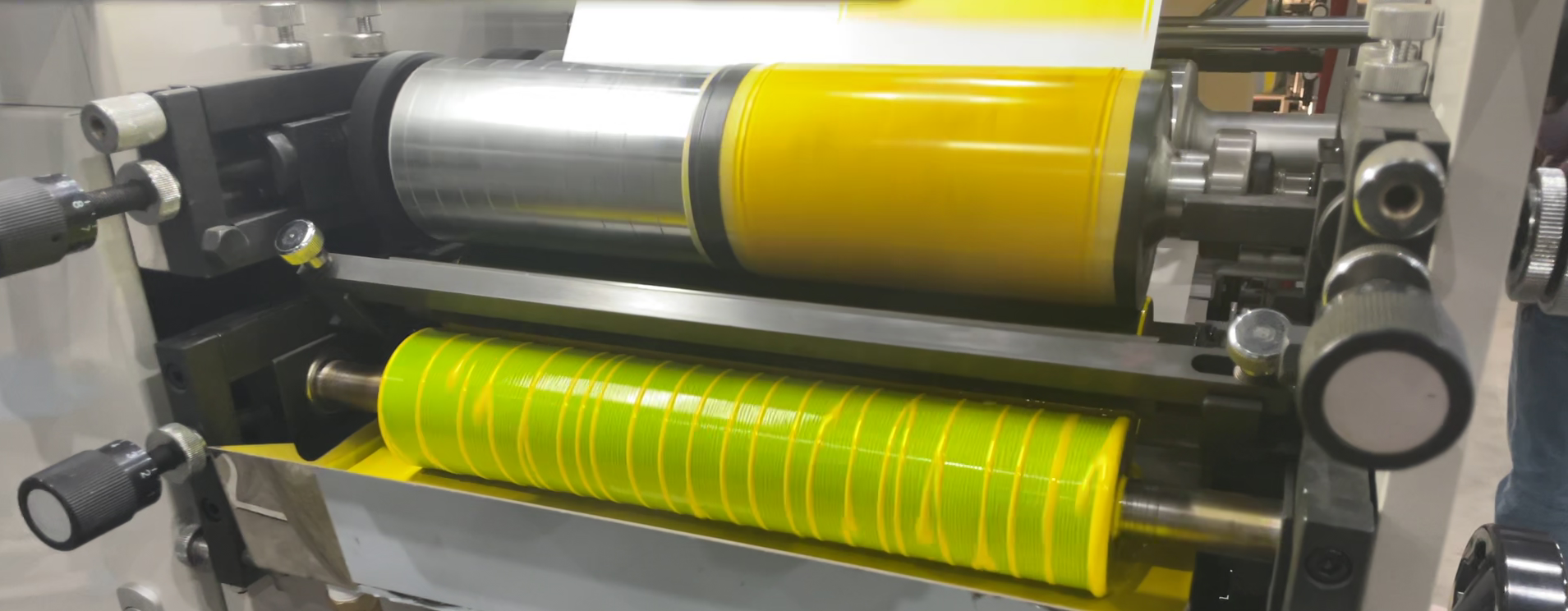

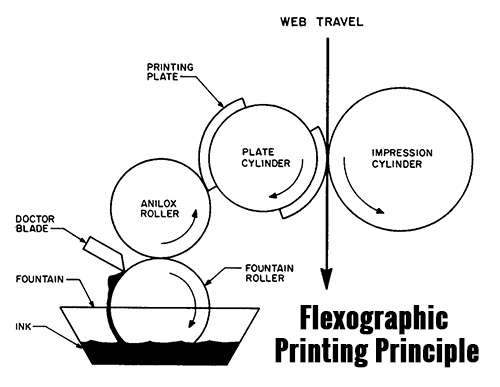

Cum excudendi, in atramento captionis cylindro (Flexilis cylindro) in atramento tristique prius transfert cruentam atramento ad atramento captionis cylindro (Afer Rollerus Rollerus translatione superfluus. In atramento est igitur aequaliter et stabiliter applicari ad superficiem printing laminam cylindri a atramento translationis cylinder; Cum printing materia (ut plastic film) transit inter printing laminam cylindri et impressionem cylindri, in graphics et textus in printing laminam sunt typis in actione pressura. Transfer ad printing materiam ad obtinere patet imagines et illud.

II. De flexo printing

Stricte Aliquam Requirements

Advocating 'green development' mainly focuses on the way of economic development, that is, emphasizing the coordination between economic development and environmental protection, and integrating reasonable and rational principles into all aspects of production and consumption, which can not only make the economy grow rapidly development and protect the ecological environment. Flexographic excudendi se est vir Green printing modum, usura aqua-fundatur, UV, et duxit UV inks.

Princeps productio efficientiam

Production speed of flexographic printing is usually above 100m/min, the production speed of satellite flexographic printing equipment is above 300m/min, and the production speed of combined printing with silk screen reaches 60~70m/min, which is much higher than letterpress printing The production speed and production efficiency of printing methods such as printing and intermittent offset printing are greatly improved. Praeterea, a Flexographic excudendi apparatus plerumque tantum requirit I ad II populus ut satus est, quae vehementer reducit labore costs.

Redigendum apparatus temperatio damna

With the widespread application of servo technology and intelligent control technology in flexographic printing equipment, as well as the popularity of petal-type flexo printing units, the setup time and loss costs of flexo printing equipment have been greatly reduced.

Diversitas et celeri laminam faciens

Cum application of laser Digital laminis-faciens technology, amet laminam-faciens paulatim subtraxit a scaenam historiae. Et laminam-faciens celeritate professionalem laminam-faciens societates crevit et laminam-faciens costs decrevit. Simul qualis aqua lavet laminis continues meliorem, venditionesque costs professionalem laser laminam-faciens machinis etiam valde reducitur. Magis et plus label printing turmas coepit instruere suis laminam-faciens apparatu et laminas, quae multum reducitur laminam-faciens et sumptus (prope Toppan). laminam faciens sumptus), idoneum parva medium amplitudo batch ordines.

Printing Quality magna melius

Et applicationem of Digital Technology, Flat-Top Dot Technology, in usum Flexilis laminis, in popularia ex petal-type flexo printing unitates et usum magno melior est qualis est flexo Typis. High-line-comitis excudendi de 175lpi / 200LPI facta est a vexillum ad flexo printing. Printing signa.

Minus obsideri limina

In technology de Flexographic excudendi apparatu manufacturers est continue meliorem, et Sales Price est relative vilis. Magis et plus label excudendi turmas sunt conversus ad obsidendam in Flexographic excudendi apparatu. In eodem tempore, ut plus foro participes, importari Flexographic excudendi apparatu Manufacturers etiam in reducendo ad Sales Price, investment constat sunt significantly reducitur.

Latae ex printing materiae

Charta (utrum superficies lenis et aspera), cardboard, CONRUGIS charta, film, aluminium ffoyle, caligarum et alia composita materiae potest typis usura flexographicali printing. Range de printing materiae multo latius printing modos ut lithography, gravus excudendi et letterpress printing.

Fortis color consistency

Cum Flexographic excudendi utitur brevi atramento iter ad translationem atramento, tota printing processus tantum includit in atramento translationem cylindro, anilox cylindro, laminam et in anilox cylindro, et atramento transfertur et diversis batches. Colo colui cultum consistency inter vestigia.

III. Application Classification of FLEXO printing

Secundum applicationem agros, flexo excudendi machinas dividitur in titulum, flexibilia packaging, cartons, charta calicem rigidum packaging et lobortis pre-printing.

Pittacium Classis

Maxime usus est in auto-tenaces label printing, hoc genus Fungi excudendi apparatus est plene muneris et includit fere omnes coniuncta functiones flexo printing apparatus, ut Cortices et laminating, flipping, calidum stampas, laminating, flipping, calidum stamps, laminating, ledo, meream, frangit, etc.

Flexibile Packaging Class

Flexo excudendi machinis flexibilia packaging sunt maxime propter charta-fundatur printing packaging materiae, ut PROMPTU MEDICA commeatus packaging sacculos, tea packaging system, etc. si instructa in corona treatment system, non potest etiam print bopp, pet etc. Plastic Plastic.

Paper Pyxidas Paper Cucurbitarum Class

Mainly used for printing on cardboard, kraft paper, coated paper, single and double PE paper, such as paper cups, paper bags, food packaging boxes, pharmaceutical packaging boxes, etc.

IV. Unicum Characteres de Flexographic excudendi

Using mollis Polymer resina laminam materia, comparari gravus excudendi, non solum reduces in laminam facere sumptus sed etiam breviora laminam faciens cycle. Ob emendationem laminam vestibulum gradu et laminam faciens technology, illud currently obvium habueris necessitates generalis packaging excudendi.

Uti anilox cylinder. Et ADLOX Rollerus sit et in atramento captionis cylindro et atramento metering cylindro. Achieves eiusdem brevi atramento semita ut gravus excudendi, et potest verius suppleret atramento secundum processus requisita, ut verius control atramentum color et atramento crassitudine. SPECTATUS modo provisum.

Nulla-pressura printing non solum reduces vibrationis et gerunt de machina et gere, in laminam, sed etiam expandit in range of printing instrumentis, praesertim prodest ad printing flexibilia materiae.

In angusto, latitudine flexographic excudendi torcular et expandit munera ex printing torcular. Praetender ut possit perficere magna post-printing processus, faciens Flexographic excudendi premere productio linea integrating printing et post-press processus.

Machinarum propter Flexographic Typographia dicuntur 'flexo excudendi apparatus '. Ad occursum diversa excudendi exigit ex users, gravida sunt developed variis genera flexo excudendi apparatus:

Fungi excudendi Machina

Türkçe

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

አማርኛ

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

Latine

Dansk

اردو

Shqip

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Māori