Flexo printing is a printing method that uses elastic letterpress plates. It has good printing quality, adapts to a wide range of printing materials, high production efficiency, convenient operation and maintenance, low investment, high profits, and meets environmental protection requirements. A series of advantages make flexo printing the printing solution of choice for various packaging products.

About flexo printing

Flexo printing is a letterpress printing method. It was originally called flexographic printing. It originated in the United States in the early 1920s. It failed to develop because the aniline dye ink used was toxic.

After that, ink manufacturers began to use colorants that were acceptable to everyone, and it was renamed flexo printing (Flexographic Process) at the 14th American Packaging Symposium in 1952.

In the 1970s, with the advancement of the materials industry, especially the advent of polymer resin plates and cermet anilox rollers, the development of flexo printing made a qualitative leap.

1. Principle of flexo printing

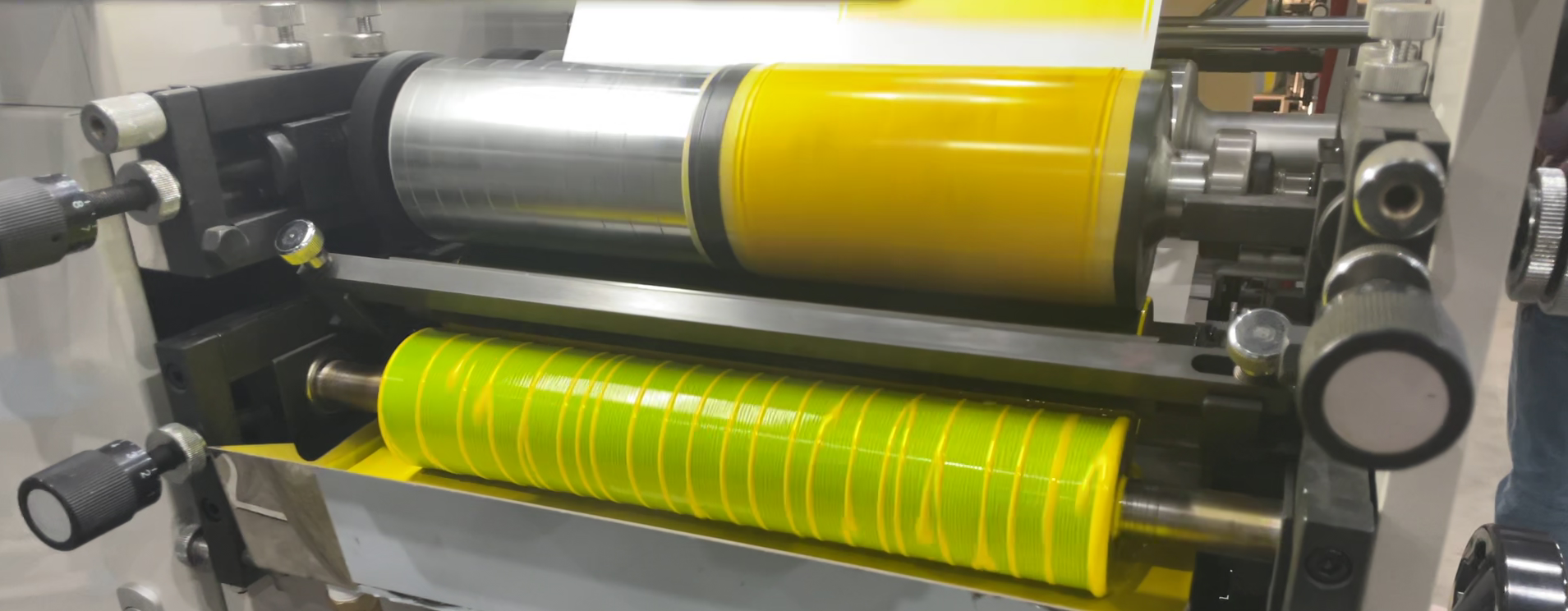

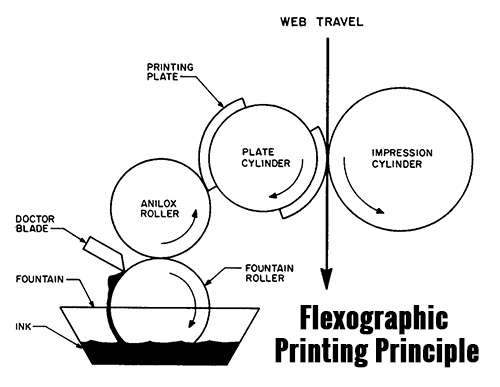

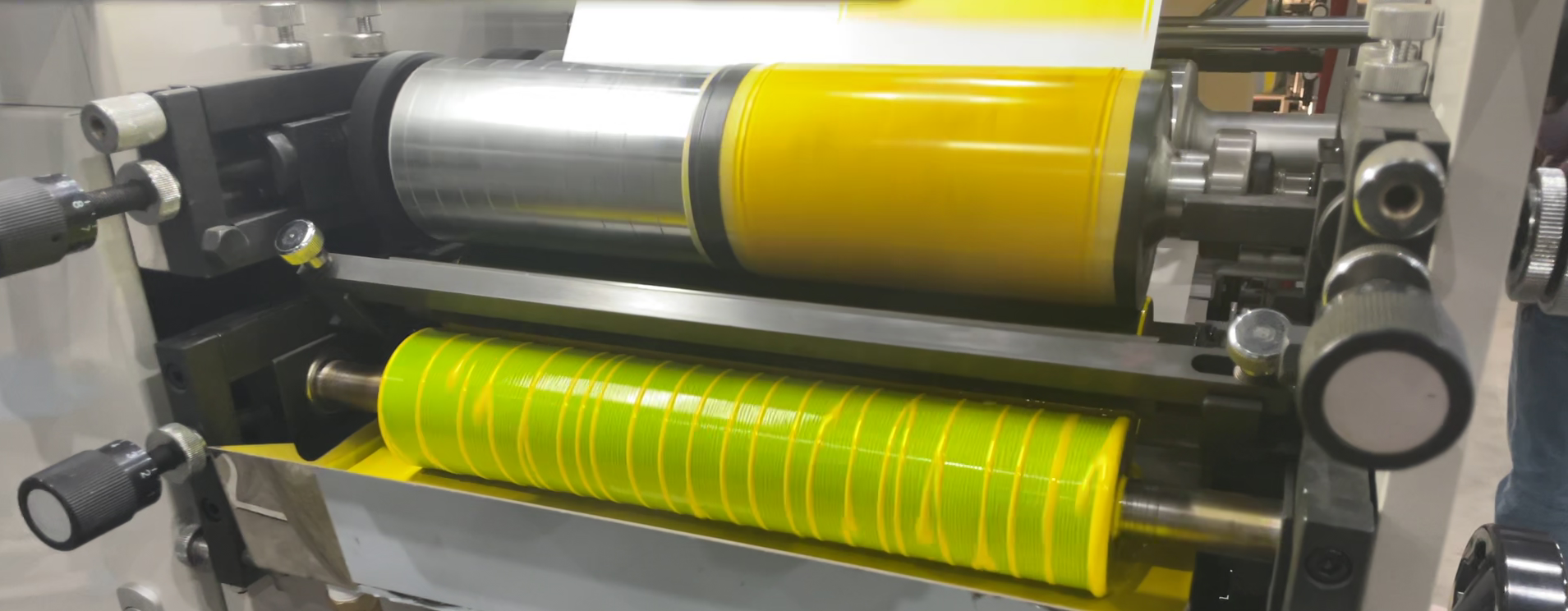

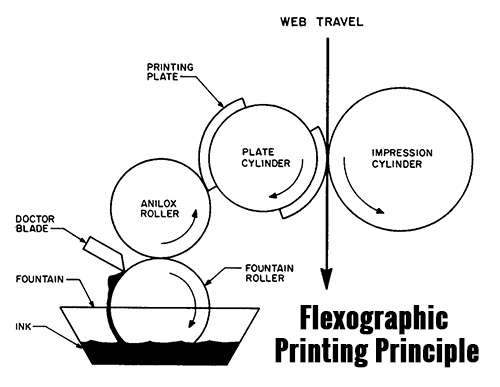

When printing, the ink transfer roller (rubber roller) in the ink tank first transfers the stained ink to the ink transfer roller (anilox metal roller), and then the ink transfer roller removes the excess ink on the surface of the anilox ink transfer roller. The ink is then evenly and stably applied to the surface of the printing plate cylinder by the ink transfer roller; when the printing material (such as plastic film) passes between the printing plate cylinder and the impression cylinder, the graphics and text on the printing plate are printed under the action of pressure. Transfer to the printing material to obtain clear images and text.

2. Characteristics of flexo printing

Strict environmental requirements

Advocating "green development" mainly focuses on the way of economic development, that is, emphasizing the coordination between economic development and environmental protection, and integrating reasonable and rational principles into all aspects of production and consumption, which can not only make the economy grow rapidly development and protect the ecological environment. Flexographic printing itself is a green printing method, using water-based, UV, and LED UV inks.

High production efficiency

Production speed of flexographic printing is usually above 100m/min, the production speed of satellite flexographic printing equipment is above 300m/min, and the production speed of combined printing with silk screen reaches 60~70m/min, which is much higher than letterpress printing The production speed and production efficiency of printing methods such as printing and intermittent offset printing are greatly improved. In addition, a flexographic printing machine usually only requires 1 to 2 people to start it, which greatly reduces labor costs.

Reduce machine adjustment losses

With the widespread application of servo technology and intelligent control technology in flexographic printing equipment, as well as the popularity of petal-type flexo printing units, the setup time and loss costs of flexo printing equipment have been greatly reduced.

Diversification and rapidity of plate making

With the application of laser digital plate-making technology, film plate-making has gradually withdrawn from the stage of history. The plate-making speed of professional plate-making companies has increased and the plate-making costs have decreased. At the same time, as the quality of water-washed plates continues to improve, the sales costs of professional laser plate-making machines have also been greatly reduced. More and more label printing companies have begun to equip their own plate-making equipment and make plates, which has greatly reduced the plate-making time and cost (close to Toppan). plate making cost), suitable for small and medium-sized batch orders.

Printing quality greatly improved

The application of digital technology, flat-top dot technology, the use of rubber plates, the popularization of petal-type flexo printing units and the use of high-line-count anilox rollers have greatly improved the quality of flexo printing. High-line-count printing of 175LPI/200LPI has become a standard for flexo printing. Printing standards.

Lower investment threshold

The technology of flexographic printing equipment manufacturers is constantly improving, and the sales price is relatively cheap. More and more label printing companies are turning to invest in flexographic printing equipment. At the same time, in order to gain more market share, imported flexographic printing equipment manufacturers also In reducing the sales price, investment costs are significantly reduced.

Wide range of printing materials

Paper (whether the surface is smooth or rough), cardboard, corrugated paper, film, aluminum foil, hose and other composite materials can be printed using flexographic printing. The range of printing materials is much wider than printing methods such as lithography, gravure printing, and letterpress printing.

Strong color consistency

Since flexographic printing uses a short ink path to transfer ink, the entire printing process only includes the ink transfer roller, anilox roller, plate roller and impression roller, and the ink is transferred through the anilox roller, which can ensure the same batch and different batches. Color consistency between prints.

3. Application classification of flexo printing

According to application fields, flexo printing machines are divided into labels, flexible packaging, cartons, paper cup rigid packaging, and carton pre-printing.

Label class

Mainly used in self-adhesive label printing, this type of flexo printing machine is fully functional and includes almost all the connected functions of the flexo printing machine, such as peeling and laminating, flipping, hot stamping, laminating, glazing, die cutting, waste discharge, Hit bumps, breaks, strips, etc.

Flexible packaging class

Flexo printing machines for flexible packaging are mainly used for paper-based printing of packaging materials, such as disposable medical supplies packaging bags, tea packaging paper, food packaging paper, non-woven fabrics, etc. If equipped with a corona treatment system, they can also print BOPP, PET etc. plastic film.

Paper boxes paper cups class

Mainly used for printing on cardboard, kraft paper, coated paper, single and double PE paper, such as paper cups, paper bags, food packaging boxes, pharmaceutical packaging boxes, etc.

4. Unique characteristics of flexographic printing

Using soft polymer resin plate material, compared with gravure printing, it not only reduces the plate making cost but also shortens the plate making cycle. Due to the improvement of plate manufacturing level and plate making technology, it currently meets the needs of general packaging printing.

Use an anilox roller. The anilox roller is both an ink transfer roller and an ink metering roller. It achieves the same short ink path as gravure printing, and can accurately supply ink according to process requirements, in order to accurately control the ink color and ink layer thickness. Favorable means are provided.

Zero-pressure printing not only reduces the vibration and wear of the machine and the wear of the plate, but also expands the range of printing media, especially beneficial to the printing of flexible materials.

The narrow-width flexographic printing press also expands the functions of the printing press. In addition to printing, it can complete a large number of post-printing processes, making the flexographic printing press a production line integrating printing and post-press processing.

Machines used for flexographic printing are called "flexo printing machine". To meet diverse printing demands from users, designers have developed various types of flexo printing machine:

Flexo Printing Machine

Türkçe

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

አማርኛ

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

Latine

Dansk

اردو

Shqip

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Māori